12

Tap the chuck / faceplate with a rubber

mallet (if needed) and pull it out.

TO INSTALL THE

CHUCK / FACEPLATE:

Remove the studs from the old faceplate /

chuck you just removed and thread them

into the faceplate / chuck you want to

install.

When threading the studs into the new

faceplate/chuck, make sure the studs are

protruding 1/2" from the check surface.

Align the studs witht holes on the spindle

nose and secure the faceplate / chuck

using the hex nuts removed.

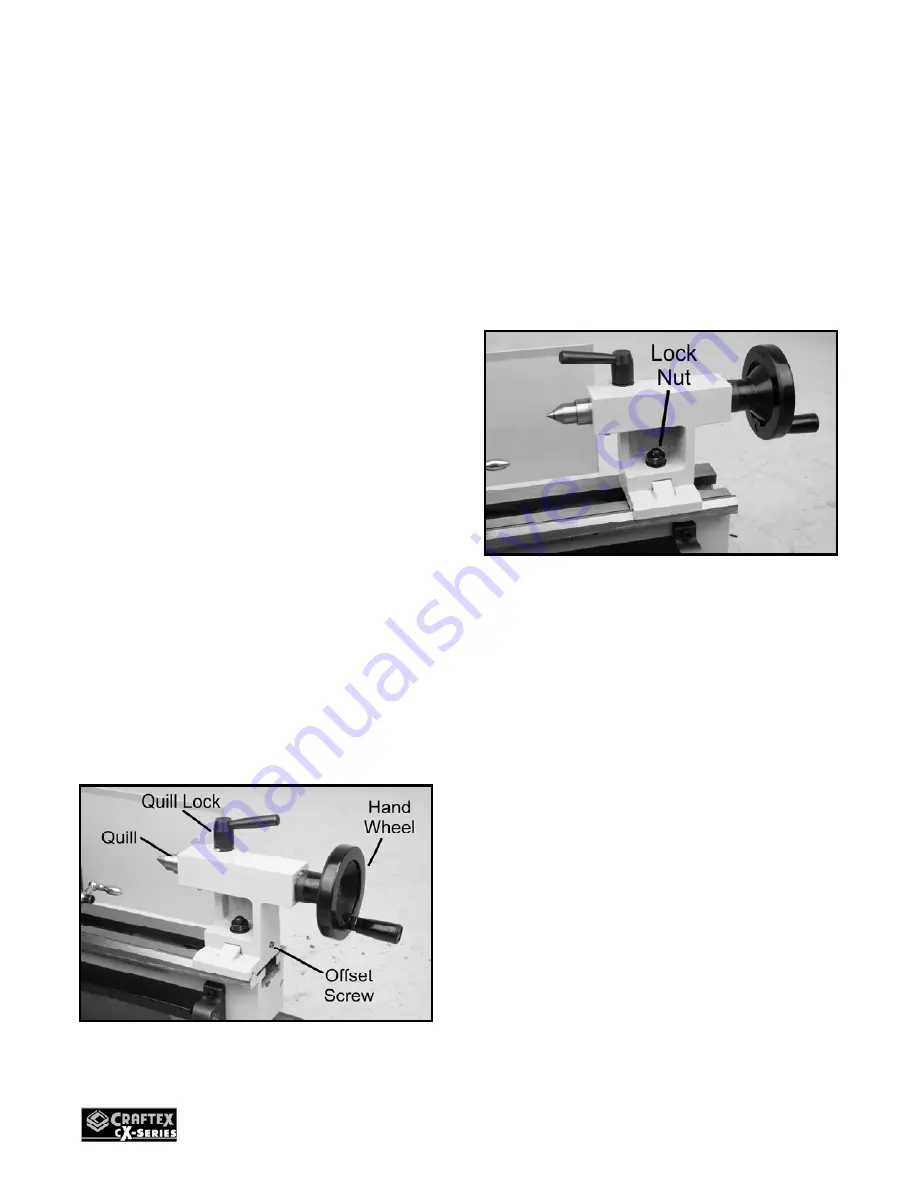

TAILSTOCK

The tailstock slides along the bed way and

can be locked in position by tightening the

hex nut on its base. The tailstock features a

hand wheel which moves the MT2 tailstock

quill in or out and a lock lever to secure the

quill in position. The offset screw on the

tailstock helps maintain tailstock position

during tailstock offset adjustment. See

figure-8.

Figure-8 Tailstock controls

TAILSTOCK POSITIONING

TO ADJUST THE LONGITUDINALLY

:

Make sure the cord is disconnected from

the power source.

Loosen the tailstock lock nut securing the

tailstock on the lathe bed with a proper size

wrench. See figure-9.

Figure-9 Loosening the tailstock lock nut

TO OFFSET THE TAILSTOCK:

Loosen the tailstock lock nut shown in

figure-9 and remove the tailstock.

Loosen the tailstock offset cap screw

shown in figure-8 a few turns and slide the

tailstock back onto the bed.

Adjust the tailstock to the desired offset and

tighten the setscrew to secure the tailstock

in position.

Remove the tailstock from the lathe bed

and tighten the offset cap screw.

Slide the tailstock back onto the lathe bed

and tighten the tailstock lock nut to secure

the tailstock in position.

Summary of Contents for CX704

Page 1: ...CX704 7 x 12 MINI METAL LATHE User Manual ...

Page 21: ...21 WIRING DIAGRAM FOR CX704 ...

Page 22: ...22 ...