Reviews:

No comments

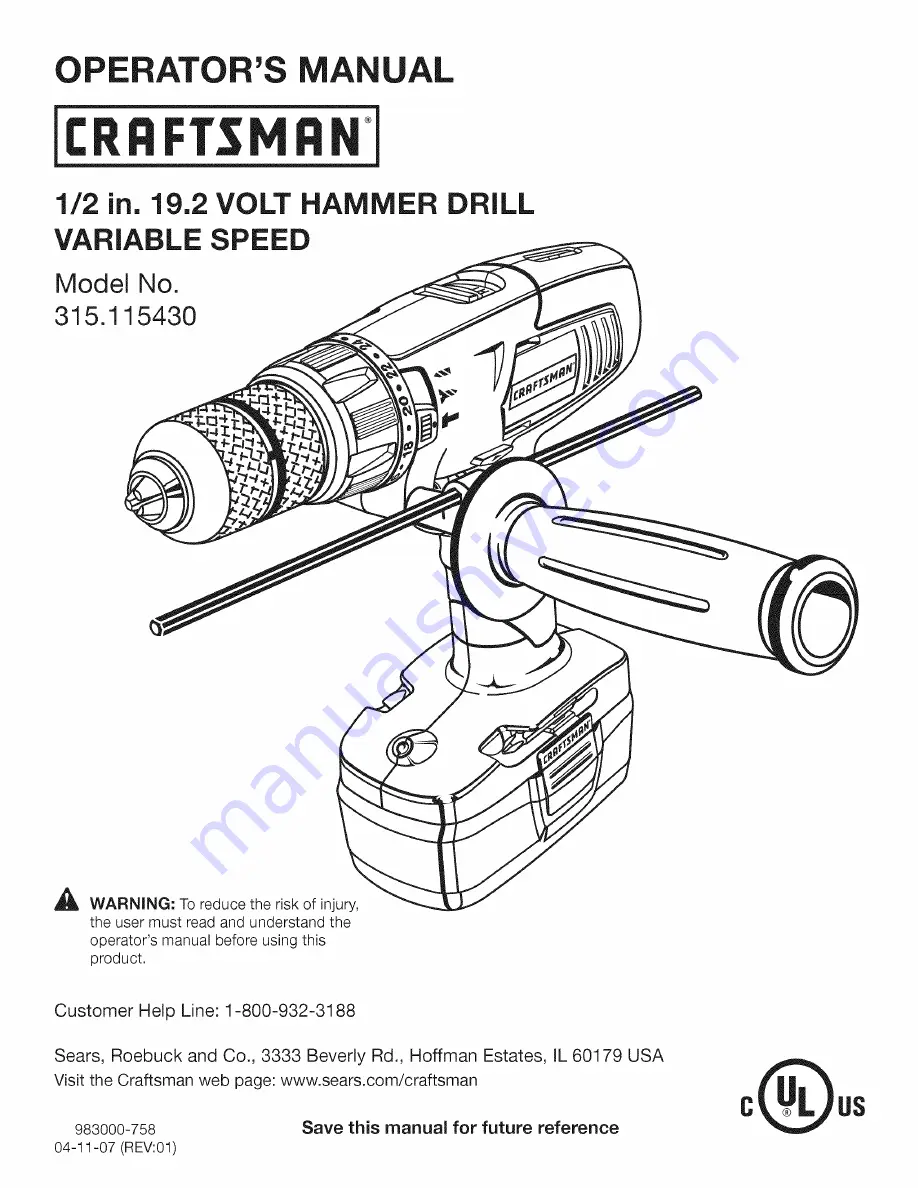

Related manuals for 11543 - C3 19.2 Volt Cordless Hammer

DDF481

Brand: Makita Pages: 11

0726-20

Brand: Milwaukee Pages: 13

PTBM 400 B1

Brand: Parkside Pages: 156

70 Series

Brand: Jiffy Pages: 6

DF332D

Brand: Makita Pages: 80

BHP448

Brand: Makita Pages: 12

6176D

Brand: Makita Pages: 1

6402

Brand: Makita Pages: 2

6096D

Brand: Makita Pages: 5

BDA341

Brand: Makita Pages: 8

6303H

Brand: Makita Pages: 20

6281D

Brand: Makita Pages: 8

BDF446

Brand: Makita Pages: 10

BHP454

Brand: Makita Pages: 60

DBM080

Brand: Makita Pages: 56

HB350

Brand: Makita Pages: 44

HP332D

Brand: Makita Pages: 20

MAGNUM

Brand: Xcalibre Pages: 20