18

19

18

19

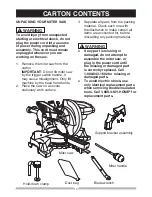

RELEASING CUTTING HEAD (FIG. G)

To avoid injury and damage to the

saw, transport or store the miter

saw with the cutting head locked in

the down position. Never use the

hold down latch to hold the cutting

head in a down position for cutting

operations.

Unlocking

1. Push down slightly on the switch

handle (1).

2. Pull out the hold-down latch (2).

3. Allow the cutting head to rise to the

up position.

Fig. G

Locking

When transporting or storing the miter

saw, the cutting head should always be

locked in the down position.

1. Push the cutting head down to its

lowest position.

2. Push the hold-down latch (2) into

the locking hole.

IMPORTANT:

To avoid damage, never

carry the miter saw by the switch

handle, the cutting arm or the miter

handle. Only lift machine by the base

hand holds.

To avoid injury, disconnect the

plug from the power source before

performing any adjustments or

repair.

WARNING

!

Fig. D

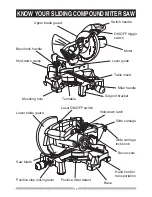

SAW BLADE WRENCH (FIG. E)

For convenient storage and prevention

of loss, there is a slot (1) in the right

side of the switch handle (2) for storing

the blade wrench (3) when not in use.

Fig. E

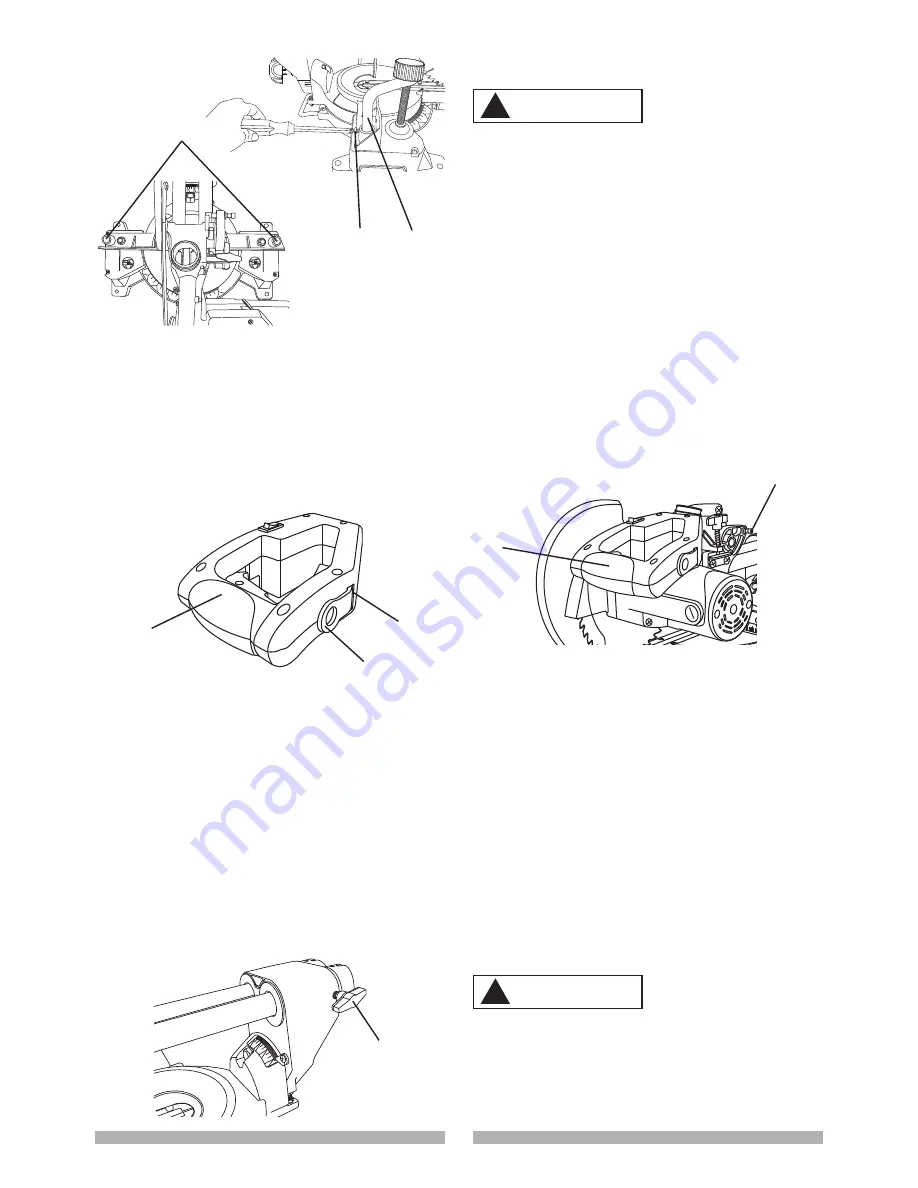

UNLOCKING THE SLIDE CARRIAGE

(FIG. F)

After removing the saw from the carton,

loosen the slide carriage lock knob

(1). When transporting or storing the

miter saw, the slide carriage should

always be locked in position. The slide

carriage lock knob (1) is located on the

right side of the slide carriage.

Fig. F

WARNING

!

1

1

2

1

3

2

2

1

3