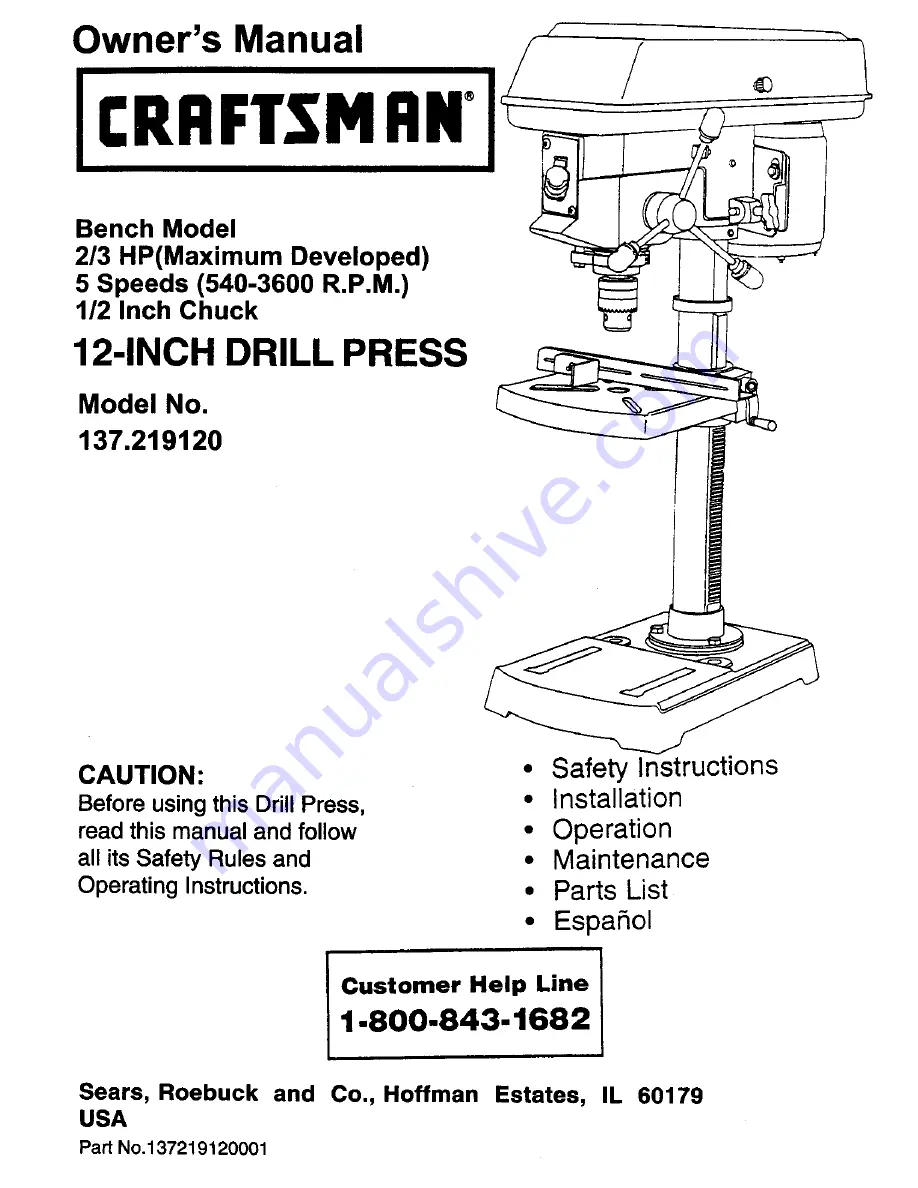

Summary of Contents for 137.219120

Page 7: ...F G H I J K L M N 0 P Q R 7 ...

Page 23: ...CRAFTSMAN12 DRILL PRESS SCHEMATIC A MODEL NO 137 219120 A gA I 23 ...

Page 25: ...CRAFTSMAN12 DRILL PRESS SCHEMATIC B MODEL NO 137 219120 45 54A 35 11 it0 25 ...

Page 27: ...CRAFTSMAN12 DRILL PRESS SCHEMATIC C MODEI NO 137 219120 59 71 70A 69 J 68 72A 64 65A 60 61 27 ...

Page 35: ...C D G H K 1 L M N 0 0 P Q 35 ...

Page 51: ...NOMENCLATURE DE LA PERCEUSE A COLONNE DE 12 PO MODELE Nu 137 219120 DIAGRAMA A 7A 8A t I 51 ...