1

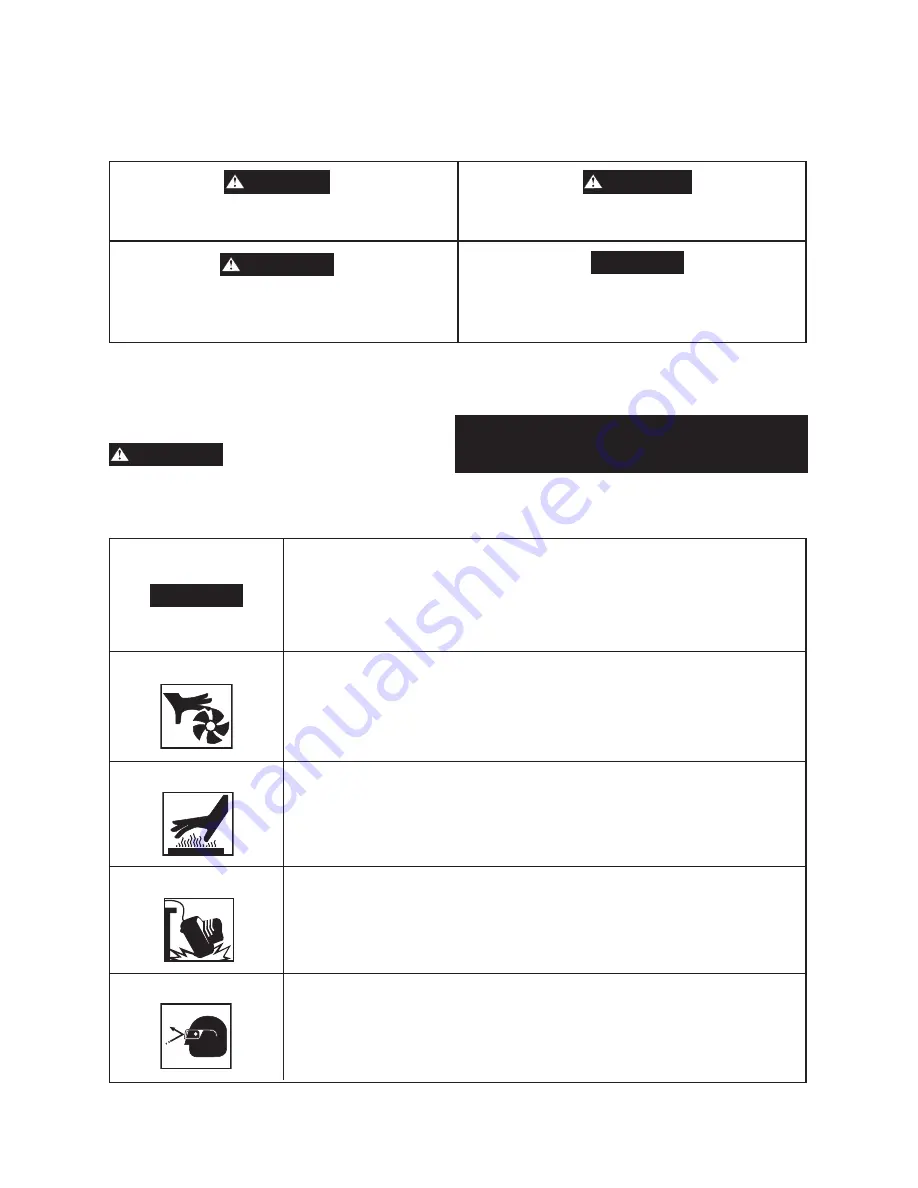

Risk of Moving Parts

If the air compressor is in operation, all guards and covers should be

attached or installed correctly. If any guard or cover has been damaged, do

not operate the equipment until the proper personnel has correctly repaired

the equipment. The power cord should be free of any moving parts, twisting

and/or crimping while in use and while in storage.

Risk of Burns

There are surfaces on your air compressor that while in operation and

thereafter can cause serious burns if touched. The equipment should be

allowed time to cool before any maintenance is attempted. Items such as the

compressor pump and the outlet tube are normally hot during and

after operation.

Important Safety Instructions and Guidelines

• Save all instructions

The air compressor should be operated on a dedicated 15 amp circuit. If the

circuit does not have 15 free amps available, a larger circuit must be used.

Always use more air hose before utilizing extension cords. All extension cords

used must be 12 gauge with a maximum length of 25 ft. The circuit fuse type

must be a time delay. Low voltage could cause damage to the motor.

CAUTION

Improper operation or maintenance of this product could result in serious injury and/or property damage. Read and

understand all of the warnings and safety instructions provided before using this equipment.

WARNING

Risk of Falling

Operation of the air compressor should always be in a position that is stable.

Never use the air compressor on a rooftop or elevated position that could

allow the unit to fall or be tipped over. Use additional air hose for

elevated jobs.

Risk from Flying Objects

Always wear ANSI Z87.1 approved safety glasses with side shields when the

air compressor is in use. Turn off the air compressor and drain the air tank

before performing any type of maintenance or disassembly of the hoses or

fittings. Never point any nozzle or sprayer toward any part of the body or at

other people or animals.

The information listed below should be read and understood by the operator. This information is given to protect the

user while operating and storing the air compressor. We utilize the symbols below to allow the reader to recognize

important information about their safety.

When used without the safety alert symbol indicates

a potentially hazardous situation which, if not

avoided, may result in property damage.

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

DANGER

CAUTION

WARNING

Safety Symbols

CAUTION

WARNING: This product contains one or more chemicals known to the

State of California to cause cancer and birth defects or other reproduc-

tive harm. Wash hands after handling.