Reviews:

No comments

Related manuals for 18178 - Full Head Framing Nailer

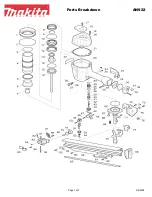

AG125

Brand: Makita Pages: 3

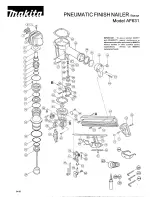

AF631

Brand: Makita Pages: 2

AN922

Brand: Makita Pages: 3

AF503

Brand: Makita Pages: 32

AN621

Brand: Makita Pages: 3

AN942

Brand: Makita Pages: 7

DBN500

Brand: Makita Pages: 24

CHN71500

Brand: Campbell Hausfeld Pages: 2

CHN70600

Brand: Campbell Hausfeld Pages: 2

IronForce IFN2190

Brand: Campbell Hausfeld Pages: 12

CHN70800

Brand: Campbell Hausfeld Pages: 1

RH Series

Brand: D'Orly Pages: 11

Rac 83

Brand: FAR Pages: 32

PET 25 A1

Brand: Parkside Pages: 44

PDRS 6.3 A1

Brand: Parkside Pages: 71

PAT 20-Li A1

Brand: Parkside Pages: 89

PSN90

Brand: Paslode Pages: 15

PHET 15 A1

Brand: Parkside Pages: 35