14

SERVICE & ADJUSTMENTS

WARNING

Do not at any time make any adjustments without first stopping

the engine, disconnecting spark plug wire and grounding it against

the engine. Always wear safety glasses during operation or while

performing any adjustments or repairs.

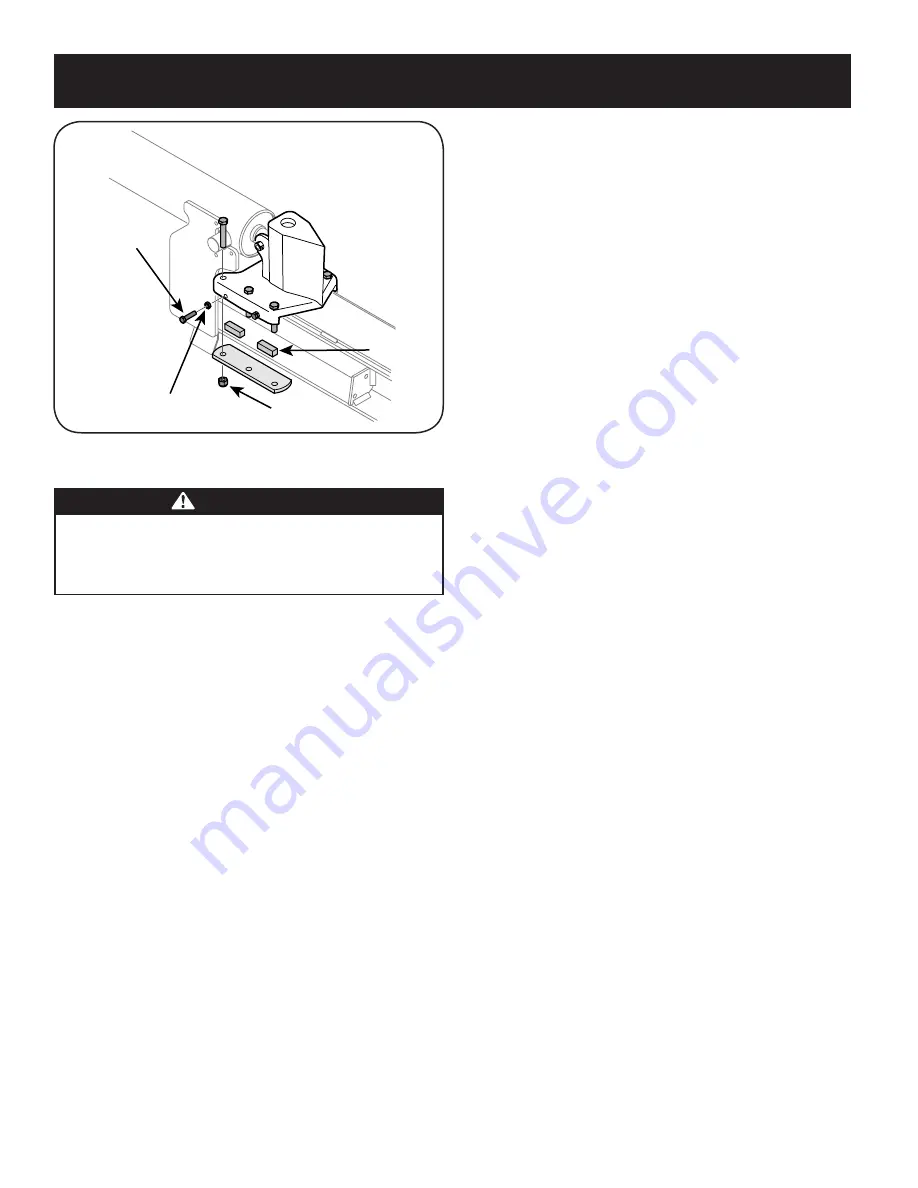

WEDGE ASSEmbLy ADJuSTmENT

As normal wear occurs and there is excessive “play” between the

wedge and beam, adjust the bolts on the side of the wedge assembly

to eliminate excess space between the wedge and the beam.

1. Loosen the jam nuts on the two adjustment bolts on the side of the

wedge. See Figure 5-1.

2. Turn the adjustment bolts in until snug and then back them off

slowly (approximately 1.5 turns) until the wedge assembly will slide

on the beam.

3. Re-tighten the jam nuts securely against the side of the wedge to

secure the adjustment bolts in this position.

GIb ADJuSTmENT

Periodically remove and replace the “gibs” (spacers) between the

wedge assembly and the back plate.

NOTE

: The gibs may be rotated and/or turned over for even wear.

1. Loosen the lock nuts under each back plate and slide the gibs out.

See Figure 5-1.

2. Turn or replace the gibs.

3. Reassemble the back plate and secure with the lock nuts.

4. Readjust the bolts on the side of the wedge assembly.

hoSE CLAmpS

• Before each use check to see if the hose clamps on the suction

hose (attached to the side of the pump) are tight. Check the hose

clamps on the return hose at least once a season.

Figure 5-1

Adjustment

Bolt

Jam Nut

Lock Nut

Gib