13

OPERATION

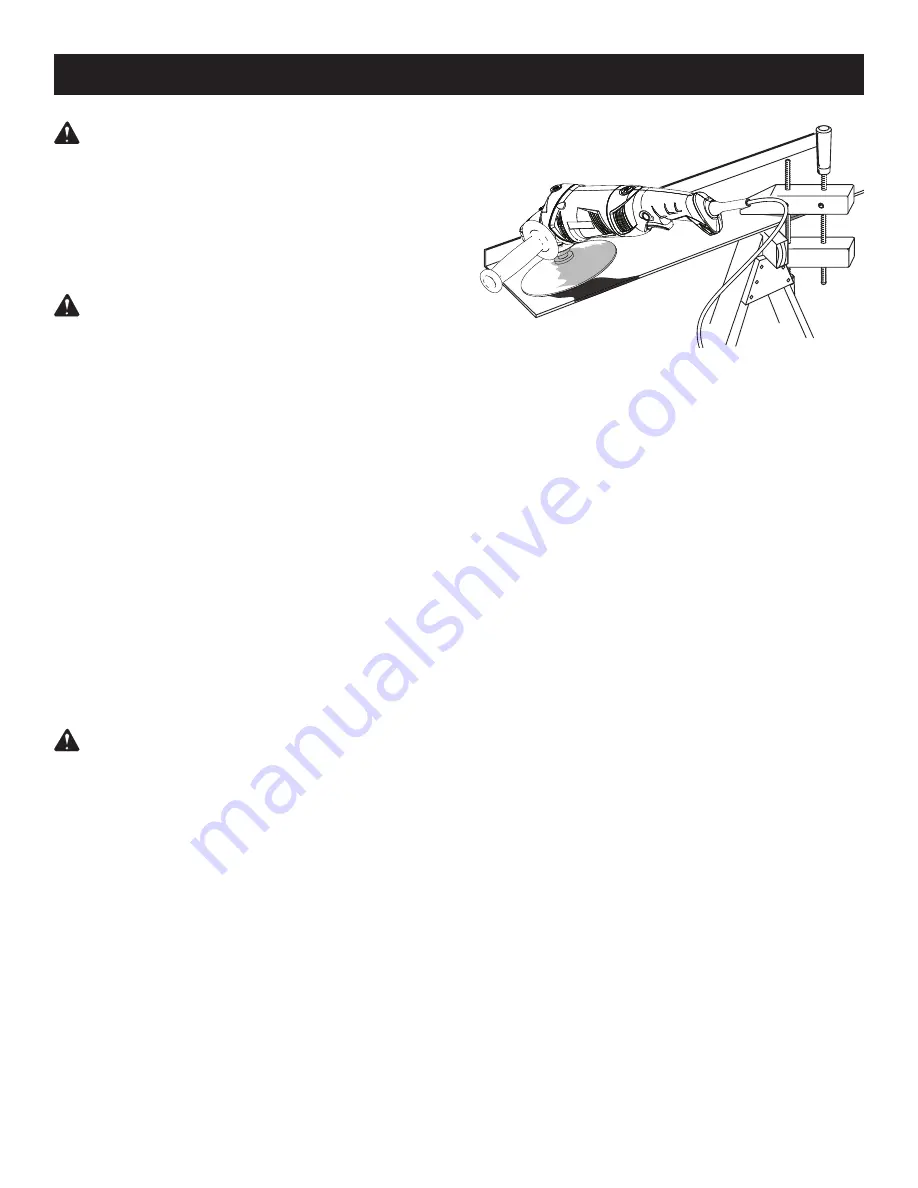

Fig. 10

SANDING DISC SELECTION

Selecting the correct size grit and type sanding disc is

an extremely important step in achieving a high quality

sanded finish. Aluminum oxide, silicon carbide, and other

synthetic abrasives are best for power sanding. Natural

abrasives, such as flint and garnet are too soft for

economical use in power sanding.

In general, coarse grit will remove the most material and

finer grit will produce the best finish in all sanding

operations.

The condition of the surface to be sanded will determine

which grit will do the job. If the surface is rough, start with

a coarse grit and sand until the surface is uniform.

Medium grit may then be used to remove scratches left by

the coarser grit and finer grit used for finishing the surface.

Always use the proper grit sanding disc, and not extra

pressure when sanding. Continue sanding with each grit

until surface is uniform.

WARNING:

To prevent loss of control and possible

serious personal injury, always operate the tool with

both hands, keeping one hand on the side handle.

SANDING

See Figure 10.

Clamp or otherwise secure the work to prevent it from

moving under your sander/polisher. Secure small workpieces

in a vise or use clamps to secure them to a workbench.

WARNING:

Unsecured work could be thrown

towards the operator causing injury.

Hold the tool in front and away from you, keeping it clear

of the workpiece. Start the tool by depressing the switch

trigger and letting the motor build to its maximum speed.

Gradually lower sander/polisher to the workpiece at a

slight (5° to 8°) angle.

Do not attempt to hold the sanding disc flat on the

workpiece. Always keep the tool in motion moving over

the work, allowing it to operate freely without unneces-

sary pressure. The weight of the unit supplies adequate

pressure, so let the sanding disc and sander do the work.

Applying additional pressure only slows the motor, rapidly

wears sanding discs, and greatly reduces sander speed.

Excessive pressure will overload the motor, causing

possible damage from motor overheating, which can

result in inferior work. Any finish or resin on wood may

soften from the frictional heat.

Do not sand too long in one spot. This will cause uneven

sanding and gouging of the work.

Upon completion of a sanding operation, lift tool away

from work surface before turning off.

WARNING:

Sanding disc must come to a complete

stop before setting tool down on workbench. Failure

to do so can cause the tool to be thrown from

workbench because of sanding disc rotation. This

could result in damage to the tool or possible serious

injury to the operator.