9

OPERATION

WARNING

:

Do not allow familiarity with tools

to make you careless. Remember that a careless

fraction of a second is sufficient to inflict serious

injury.

WARNING

:

Always wear safety goggles or safety

glasses with side shields when operating power

tools. Failure to do so could result in objects being

thrown into your eyes resulting in possible serious

injury.

WARNING:

Do not wear loose clothing or jewelry

when operating this tool. They could get caught in

moving parts causing serious injury. Keep head away

from sander/polisher and sanding or polishing area.

Hair could be drawn into sander/polisher causing

serious injury.

WARNING:

Do not hold the rubber disc with one

hand and use the power of the sander/polisher to

tighten the rubber disc on the spindle. The sander/

polisher could slip in your hand, or cause an

accident resulting in serious personal injury.

WARNING:

Always unplug the tool when installing

or removing disks, adjusting settings, or when the

tool is not in use. Failure to unplug the tool may

result in accidental starting and serious personal

injury.

A

P

PLICATIONS

You may use this tool for the purposes listed below:

Sanding on wood and wood product surfaces

Removing rust from and sanding steel surfaces

Polishing and buffing painted surfaces

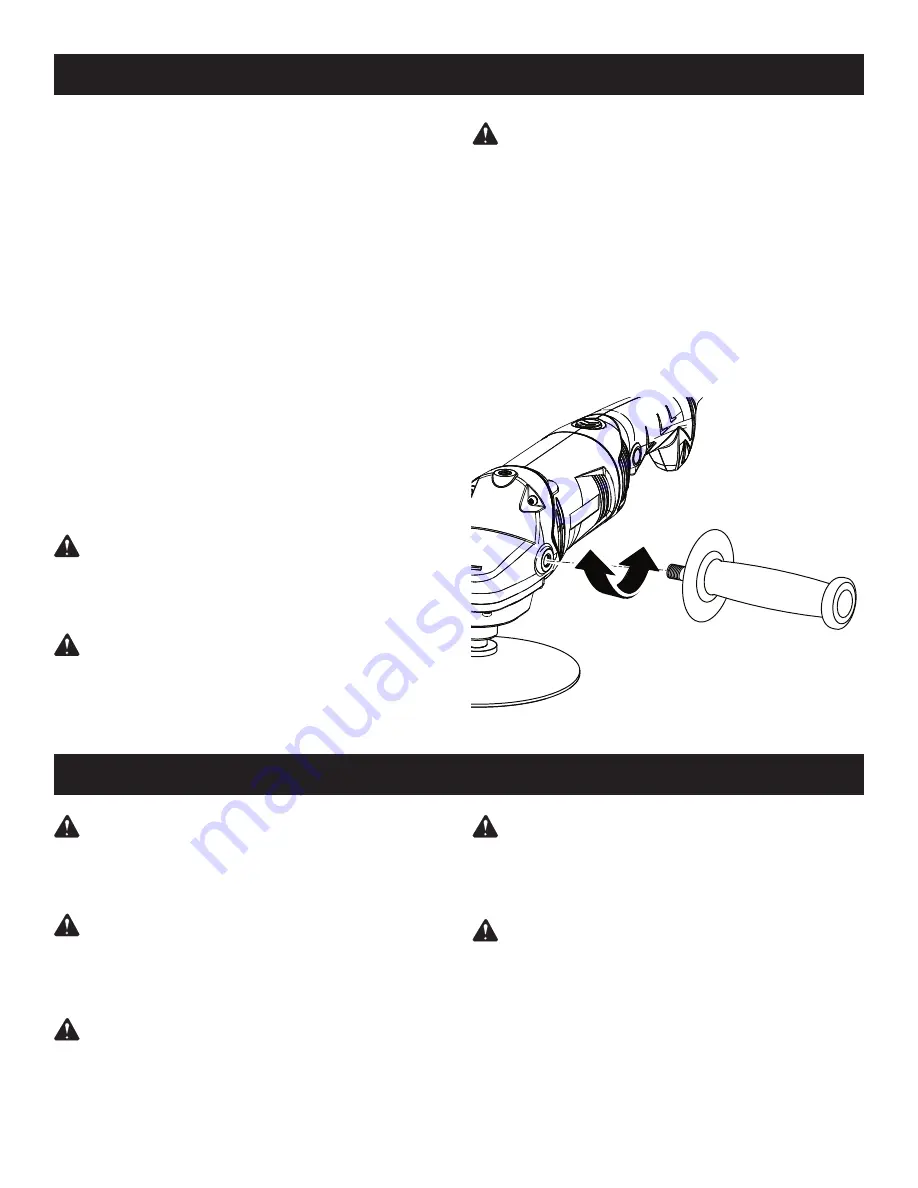

INSTALLING THE SIDE HANDLE ASSEMBLY

See Figure 2.

�

Unplug the sander/polisher.

Insert the handle assembly to the desired operating

position.

Securely tighten by turning the handle assembly

clockwise.

NOTE:

The side handle must always be used to prevent

loss of control and prevent injury.

Fig. 2

TO

TIGHTEN

TO

LOOSEN

UNPACKING

This product has been shipped completely assembled.

Carefully remove the tool and any accessories from the

box. Make sure that all items listed in the packing list

are included.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-932-3188 for assistance.

PACKING LIST

Sander/Polisher

Side Handle

Rubber Disc

Polishing Bonnet

Spanner Wrench

Spanner Nut

Operator’s Manual

WARNING

:

If any parts are damaged or missing

do not operate this tool until the parts are replaced.

Failure to heed this warning could result in serious

personal injury.

WARNING

:

Do not attempt to modify this tool

or create accessories not recommended for use

with this tool. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

FEATURES

WARNING:

Do not connect to power supply until

assembly is complete. Failure to comply could result

in accidental starting and possible serious injury.