OPERATOR’S MANUAL

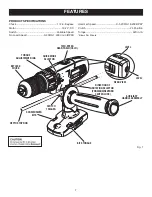

Model No.

315.115430

1/2 in. 19.2 VOLT HAMMER DRILL

VARIABLE SPEED

Save this manual for future reference

WARNING:

To reduce the risk of injury,

the user must read and understand the

operator’s manual before using this

product.

Customer Help Line: 1-800-932-3188

Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

983000-759

11-21-07 (REV:02)

BATTERIES AND cHARGERS

SOLD SEPARATELy