13

n

Move the sander slowly over the work surface, using

the rear handle to control the sander and the front

handle to guide the sander.

NOTE:

Allowing the sander to remain in one place will

result in an uneven surface.

The sander is designed to provide the proper weight on

the sanding belt.

If the sanding belt slips or does not track while sanding,

you may be applying too much pressure.

Excessive pressure will result in uneven work, clogged

sanding belts, premature sanding belt wear, possible

motor burnout, and irregular sanding belt tracking

When this occurs, remove the sander from the workpiece.

If you properly adjust the belt tracking, the sanding belt

will return to its normal and correct position on the drive

roller and front roller.

Use a coarser sanding belt for heavy sanding, not heavy

pressure. The weight of the tool is sufficient to provide

adequate pressure at the correct location.

The front roller of the sander is not designed for contour

sanding. Sanding on the front roller could cause

irregularity in the sanding belt tracking.

OPERATING THE SANDER

See Figure 10.

n

Secure the work to prevent it from moving under the

sander.

WARNING:

Unsecured work could be thrown

towards the operator causing injury.

n

Turn the sander on and let the motor reach its

maximum speed before placing the sander on the work

surface.

n

Lower the sander to the work surface with a slight

forward motion.

WARNING:

Keep a firm grip on the sander with

both hands at all times. Failure to do so could result

in loss of control leading to possible serious injury.

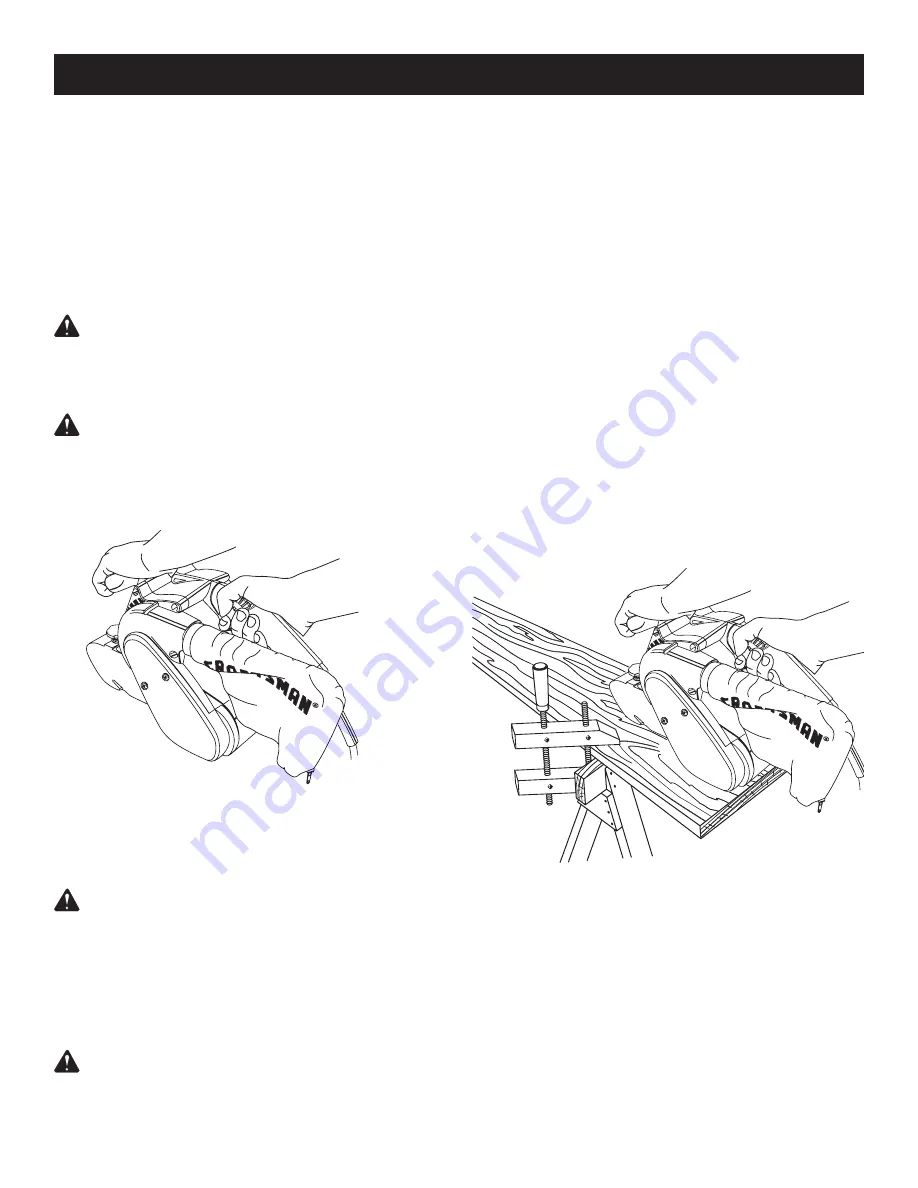

PROPER HAND PLACEMENT

See Figure 9.

For ease of operation and maintaining proper control,

the sander has a front handle and a rear handle. These

handles allow two-handed operation, which aids in

maintaining control, keeping the sanding area level with

the workpiece, and keeping hands clear of the sanding

belt. When operating the sander, always hold the front

handle with your left hand and the rear handle with your

right hand.

WARNING:

Keep hands and fingers clear of

moving sanding belt, front idler roller, and drive

roller assembly. Failure to do so will result in serious

personal injury.

WARNING:

Do not let your fingers rest over the

front or right edge of the sander. If the sanding belt

were to run off, or if it were not properly adjusted,

your fingers could come in contact with the moving

sanding belt resulting in possible serious injury.

OPERATION

Fig. 10

Fig. 9