11

ATTACHING SANDER TO VACUUM

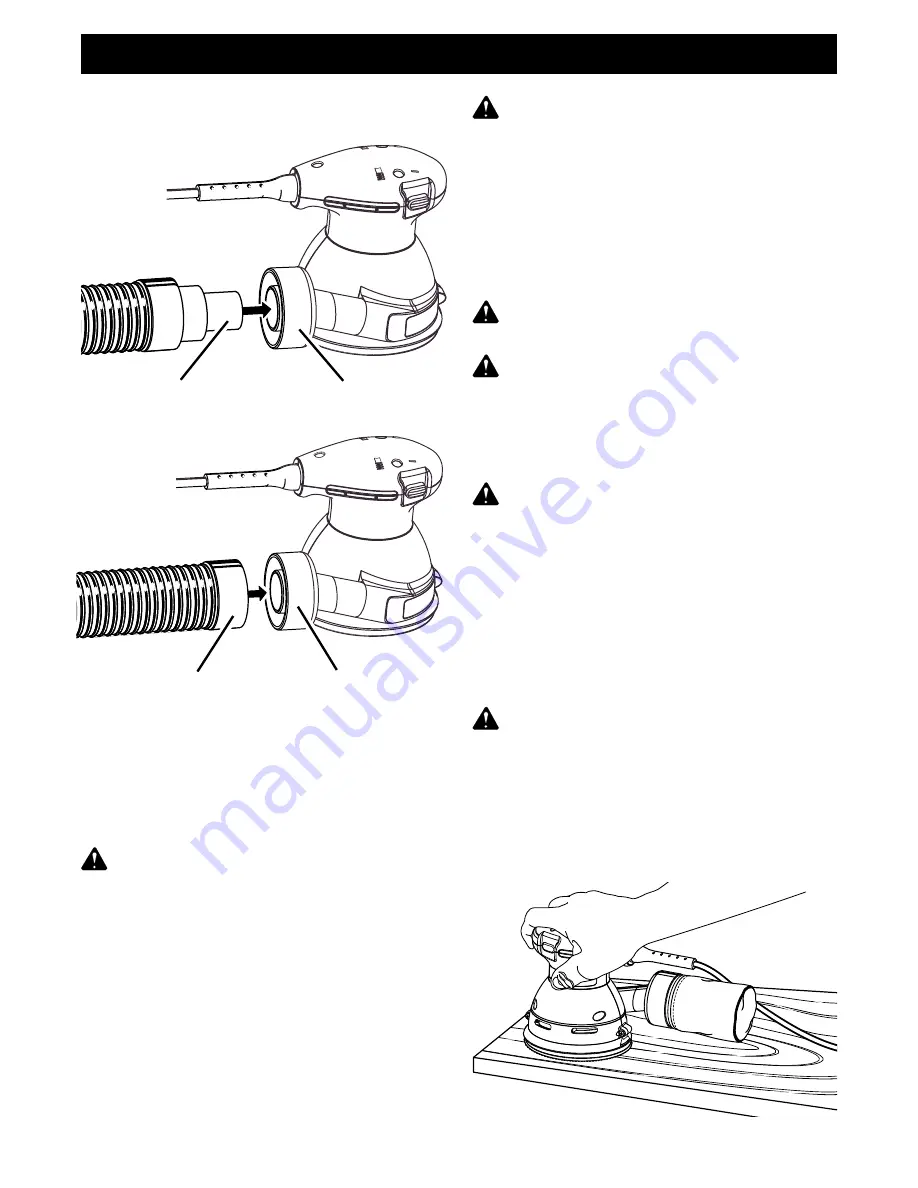

See Figures 8 and 9.

OPERATION

Fig. 8

Fig. 9

1-1/4 in. VACUUM

HOSE CONNECTION

2-1/2 in. VACUUM

HOSE CONNECTION

BLOWER

EXHAUST

BLOWER

EXHAUST

WARNING:

When sander is not connected to

vacuum, always reinstall dust bag assembly back

on sander. Failure to do so could cause sanding

dust or foreign objects to be thrown into your face

or eyes which could result in possible serious

injury.

PREPARING FOR OPERATION

Clamp or otherwise secure the work to prevent it from

moving under your sander.

WARNING:

Unsecured work could be thrown

towards the operator causing injury.

WARNING:

Always wear safety goggles or

safety glasses with side shields when operating

your sander. Failure to do so could result in

foreign objects being thrown into your eyes,

resulting in possible serious injury. If the sanding

operation is dusty, also wear a face or dust mask.

WARNING:

Do not wear loose clothing or

jewelry when operating sander. They could get

caught in moving parts causing serious injury.

Keep head away from sander and sanding area.

Hair could be drawn into sander causing serious

injury.

SANDING

See Figures 10 and 11.

Place sander on workpiece so that all of sanding disc

surface is in contact with workpiece.

CAUTION:

Be careful not to let your hand cover

the air vents.

Start your sander and move it slowly over workpiece

making successive passes in parallel lines, circles, or

crosswise movements. Upon completion of sanding

operation, turn sander off and wait until sanding disc

comes to a complete stop before removing from

workpiece.

When sanding for an extended period of time, you can

easily attach the dust collection system of your sander

to a vacuum.

TO ATTACH:

■

Unplug your sander.

WARNING:

Failure to unplug your sander could

result in accidental starting causing possible

serious personal injury.

■

Remove dust bag assembly from sander.

■

Attach vacuum hose to blower exhaust as shown

in either figure 8 or 9, depending upon the size

vacuum hose you are using.

Note: Vacuum hose fits inside blower exhaust.

Figure 8 illustrates a standard 1-1/4 in. vacuum

hose connection, while figure 9 illustrates a stan-

dard 2-1/2 in. vacuum hose connection.

■

Connect sander and vacuum to power supply.

■

Your sander is now ready for operation.

Fig. 10

TYPICAL SANDING OPERATION