5

Maintenance

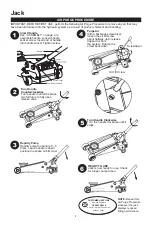

To Add Oil:

• Position jack on the level ground and lower

the saddle.

• Remove the oil fill screw.

• Fill the oil reservoir until oil level is just over

the top surface of the inner cylinder. Replace

oil plug.

• Perform Air Purge Procedure described on

page 2.

To Replace Oil:

• Fully open release valve by turning handle

counterclockwise as far as it will go.

• Remove the oil fill screw. Turn the jack over

so that old oil will drain from the oil fill hole.

• Turn the jack back over after the oil has

drained. Refill through oil fill hole. Keep dirt

and other material clear when pouring. Fill to

just beneath lower rim of hole. Replace oil fill

screw.

• Perform Air Purge Procedure described on

page 2.

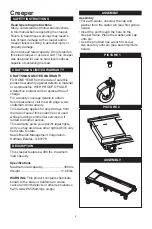

Lubrication

• Add lubricating oil (WD-40) to all moving parts

when needed.

• For light duty use, lubricate every six months.

• For heavy and constant use, lubrication is

recommended every month.

MAINTENANCE

Rust Prevention:

• Check ram and pump plunger on the Power

Unit Assembly every two months (or sooner,

based on usage) for any signs of rust or

corrosion. Lift the jack as high as it goes

and look under and behind the lifting arm. If

signs of rust are visible clean as needed and

wipe down with with an oily cloth or cloth

sprayed with WD-40.

• When storing the jack, always have the

saddle and pump plunger in the down

postion.

ALWAYS USE A GOOD GRADE

HYDRAULIC JACK OIL. DO NOT USE

HYDRAULIC BRAKE FLUID, ALCOHOL,

GLYCERINE, DETERGENT, MOTOR

OIL OR DIRTY OIL. USE OF AN UN-

RECOMMENDED FLUID CAN CAUSE

DAMAGE TO YOUR JACK.

Air Purge Procedure

During shipment, air may get into the

hydraulic system causing reduced lifting

performance. Perform Air Purge Procedure

described on page 2.

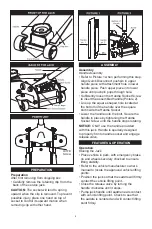

• Continue to pump jack handle to lift vehicle to

desired height.

• After lifting, support the load with

appropriately rated vehicle support stands

before working on vehicle.

WARNING:

Never work on, under, or around a

load supported only by a hydraulic jack.

Lowering the Jack

• Raise load high enough to clear jack stands;

then carefully remove the stands.

• Carefully open the release valve by slowly

turning the handle counterclockwise.

• After removing jack from under vehicle, if

saddle has not fully descended, push it all the

way down. This will reduce ram exposure to

rust and contamination.

Summary of Contents for 48181

Page 11: ...11 NOTE ...