13

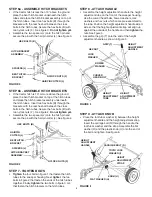

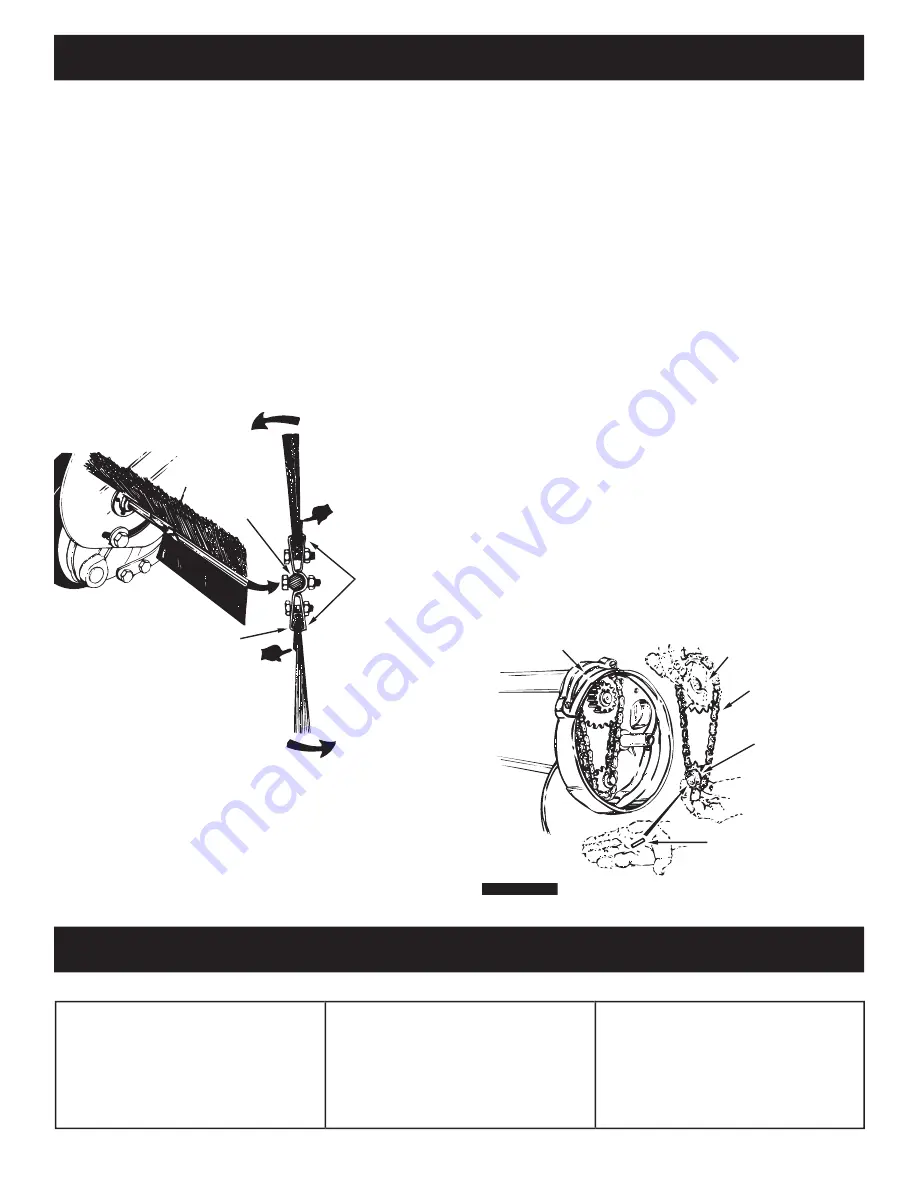

SPROCKET, CHAIN AND PAWL SERVICE

IMPORTANT: Do not remove both wheels at the same

time to avoid mixing of parts. (The R.H. and L.H. ratchet

sprockets are not interchangeable.)

Make notes on the

position of washers and snap rings during disassembly.

• Remove the dust cover by removing the two rivets

which fasten it to the wheel housing. (It is not

necessary to remove the dust cover if you are only

cleaning and lubricating the chain and sprockets.)

• Remove the retaining rings and washers which hold

the sprockets onto the shafts.

• Remove the chain and both sprockets, holding them in

position and sliding them off both of the shafts. (Look

for the drive pin, which may fall out of the brush shaft

when the ratchet sprocket is removed.) See fi gure 24.

• To reassemble, insert the drive pin through the hole

at the end of the brush shaft. Make sure the pin slides

back and forth easily in the shaft.

• Lightly grease both shafts and the chain, and fi ll the

ratchet sprocket with grease. Assemble the chain with

both sprockets back onto the shafts.

• Lightly grease the axle and then reassemble the wheel.

The brushes should rotate

only during forward rotation

of the wheel. If the brushes are driven (rotated) by both

forward and reverse rotation of the wheel, the drive pin

is jamming in the ratchet gear. Disassemble and clean

and lubricate the drive pin and ratchet gear.

BRUSH REPLACEMENT

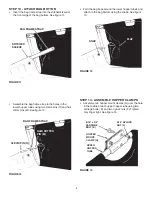

NOTE: Brush replacement should be done one brush at

a time.

• Remove the hopper bag from the sweeper.

• Loosen the hex bolts and lock nuts on two single

brush retainers which clamp one brush to the double

brush retainers.

Do Not loosen or remove the bolts

which fasten the double brush retainers to the brush

shaft. See fi gure 23.

• Slide the brush out of the retainers, noting on which

side of the brush the bristles overlap. See fi gure 23.

• Install new brush, making sure the bristles overlap on

the same side of the brush as before. See fi gure 23.

GEAR SPROCKET

CHAIN

RATCHET

SPROCKET

DRIVE PIN

DUST COVER

BRUSH ROTATION

BRUSH ROTATION

OVERLAP

BRISTLES

OVERLAP

BRISTLES

SINGLE

BRUSH

RETAINERS

DOUBLE BRUSH RETAINER

BRUSH

SHAFT

FIGURE 23

• Brushes set too low.

• Brushes are jammed

• Wheels are jammed.

Wheels skid when sweeping.

• Adjust height till brushes are 1/2"

down into grass.

• Stop sweeper. Remove obstruction.

• Remove one wheel at a time to check

for obstruction or damage. Refer to

Service and Adjustments section.

SERVICE AND ADJUSTMENTS

TROUBLESHOOTING