4

ASSEMBLY

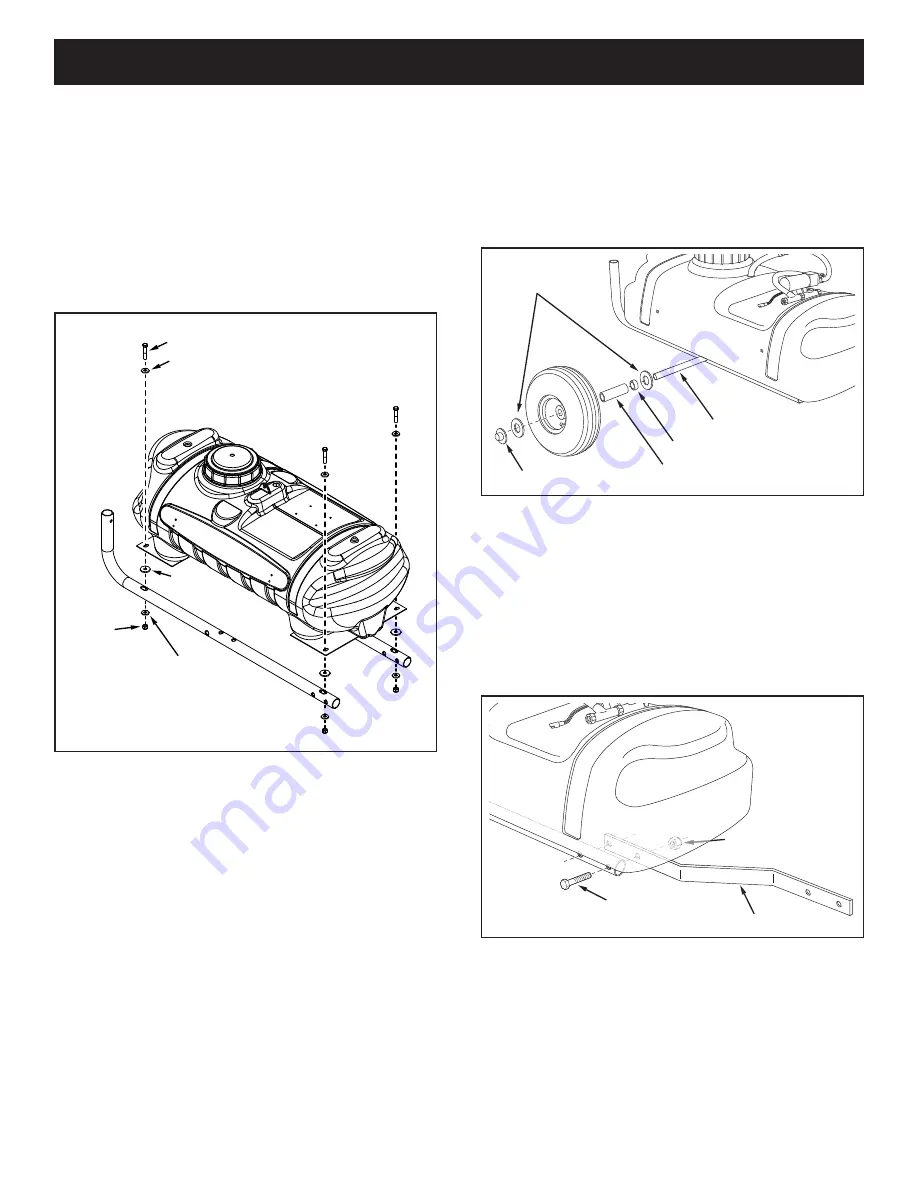

FIGURE 2

TOOLS REQUIRED FOR ASSEMBLY

(2) 1/2" Wrenches

(1) Screwdriver

(1) Pliers

(1) Hammer

• Assemble axle through holes in frame tubes. You may

need to slightly loosen bolts in frame tubes to make

the axle fit. Retighten bolts only enough to flatten the

lock washers.

• Assemble a 1/2" flat washer, a short spacer, a long

spacer, a wheel, and another 1/2" flat washer onto

the axle. Lightly tap a palnut onto the end of the axle.

Repeat on other end of axle.

1/2" FLAT

WASHER

LONG SPACER

AXLE

PALNUT

SHORT SPACER

•

Attach mounting plates to frame tubes using four 5/16

x 1-3/4" hex bolts, 3/8" washers, thick washers placed

between the mounting plates and frame tubes, 3/8"

washers, and 5/16" nylock nuts.

Tighten

the bolts.

FIGURE 1

3/8" WASHER

3/8" WASHER

5/16 x 1-3/4" HEX BOLT

THICK

WASHER

5/16"

NYLOCK

NUT

FIGURE 3

• Assemble a hitch arm to the inside of a frame tube

underneath the tank. Use two 5/16" x 2" hex bolts and

5/16" nylock nuts as shown in figure 3.

Do not tighten

yet.

Repeat for other side.

5/16" x 2"

HEX BOLT

5/16" NYLOCK NUT

HITCH ARM