7

OPERATION

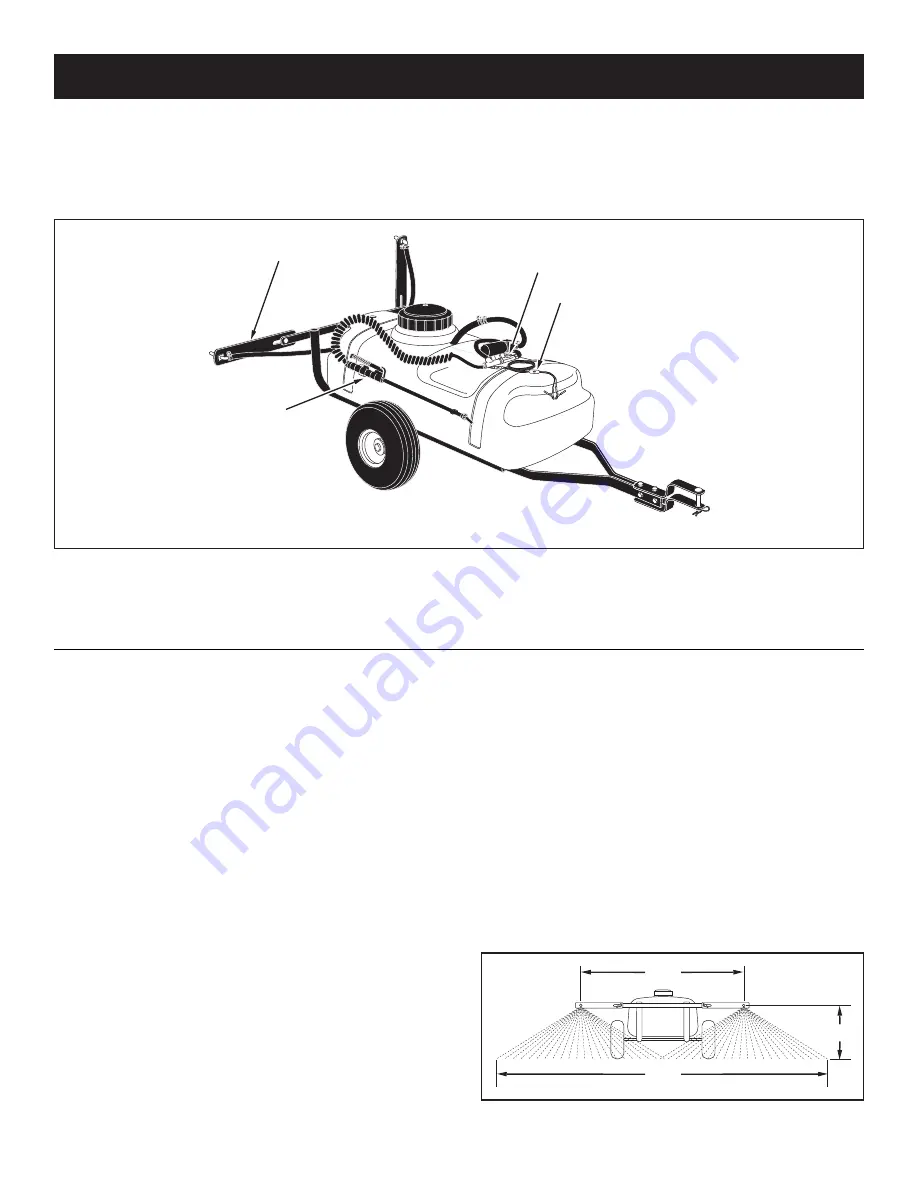

KNOW YOUR SPRAYER

Read this owner's manual and safety rules before operating your sprayer.

Compare the illustration below with your sprayer to familiarize yourself with the various controls and their locations.

FIGURE 12

BOOM ARM

Swivels up and down and adjusts in and out

to obtain proper nozzle positioning.

SPRAY GUN

Unhooks from tank for spraying shrubs,

small trees or areas inaccessible to the towed sprayer.

ON-OFF VALVE

Turns the flow on or off from the pump to

the boom nozzles.

ON-OFF SWITCH

Turns pump/motor on or off.

BEFORE STARTING

It is important

to test the boom and spray gun with plain

water before attempting actual spraying. This will enable

you to check the sprayer for leaks and to set the spray

pattern and nozzle pressure. If a leak should occur, thread

tape may be used to better seal the fitting.

PUMP PRESSURE SWITCH

The pump is equipped with a pressure switch. The

pressure switch senses outlet pressure of the pump

and will turn off the electrical power to the pump at a

predetermined high pressure point (35 PSI). If the flow

demand is very low, the pump may reach this high

pressure point and the switch will cause "cycling" (the

pump cycles on and off rapidly). This is not a problem

unless the pump is subject to continuous cycling within

one second intervals for long periods of time.

ON-OFF ADJUSTMENT OF BOOM NOZZLES

The sprayer is equipped with an "On-Off" valve for the

boom which allows the flow to the boom nozzles to be

shut off.

ADJUSTING SPRAY GUN NOZZLE

Turn the nozzle on the spray gun to adjust the spray from

a cone shaped fine mist to a straight stream. Maximum

gun pressure is attained with the ON-OFF valve shut off.

SETTING THE BOOM FOR SPRAYING

The correct positioning of the boom places the nozzles

approximately 40" apart and 14" above the ground. This

gives a spray width of approximately 80" with a slight

center overlap. See figure 12.

a. Slide the boom bars out to the ends of the slots.

b. Swivel the boom bars until the nozzles are

approximately 14" above the ground.

c. Make sure the nozzles are adjusted so that the

openings point straight down.

80"

40"

14"

ON-OFF SWITCH

ON-OFF VALVE

SPRAY GUN

BOOM ARM