12

CHECK FOR LOOSE FASTENERS

•

Before each use make a thorough visual check of

the spreader for any bolts and nuts which may have

loosened. Retighten any loose bolts and nuts.

CHECK FOR WORN OF DAMAGED PARTS

• Check for worn or damaged parts before each use.

Repair or replace parts if necessary.

CHECK TIRE INFLATION

• Check if tires are adequately inflated before each

use. Do not inflate beyond maximum recommended

pressure.

Service Dates

Bef

ore each use

After each use

Ev

ery season

Bef

ore stor

age

As instr

ucted

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service.

Check for loose fasteners

X

Check for worn or damaged parts

X

X

Check tire inflation

X

Cleaning

X

X

Lubricate

X

X

CUSTOMER RESPONSIBILITIES

• Read and follow the maintenance schedule and the maintenance procedures listed in this section.

MAINTENANCE/STORAGE

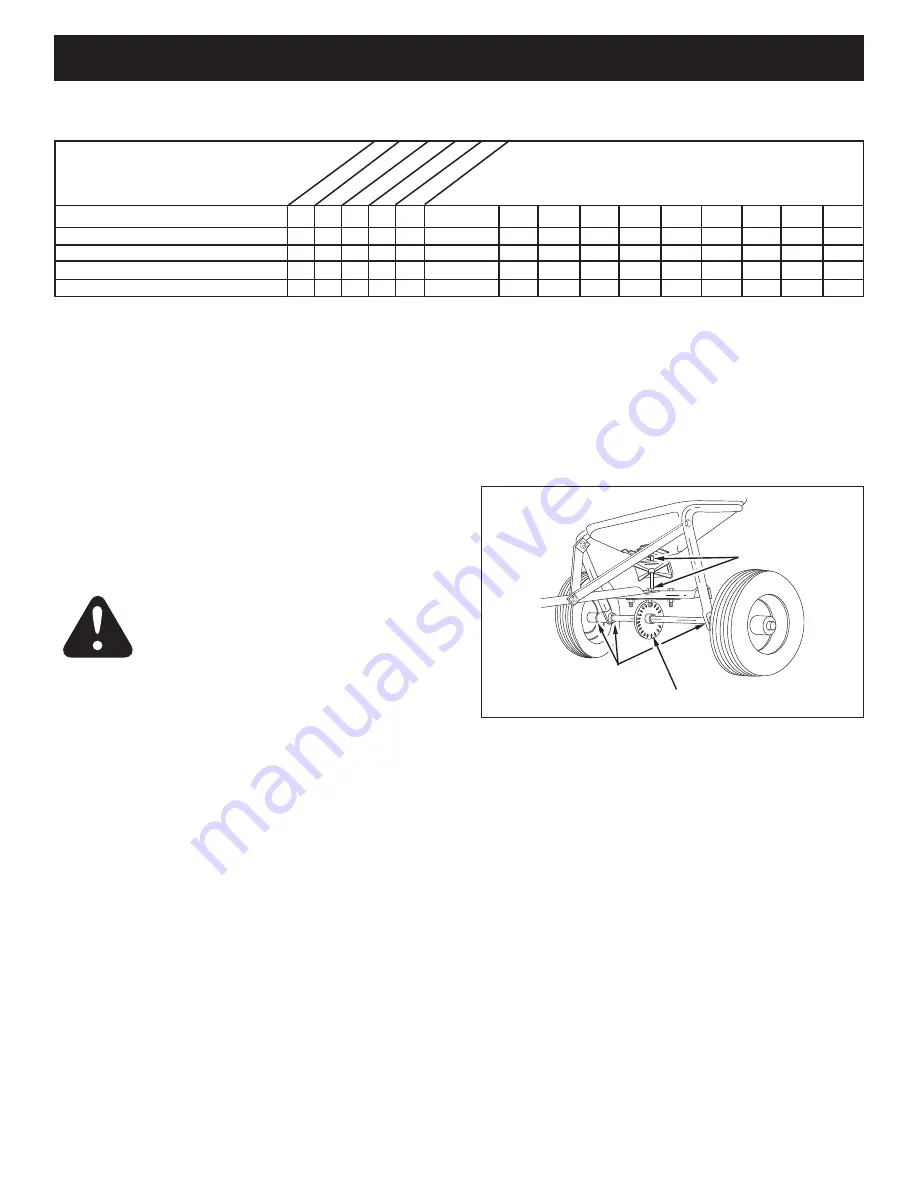

FIGURE 18

STORAGE

• Rinse inside of hopper and exterior of spreader and

dry off before storing.

• Store in a clean, dry area.

CAUTION: DO NOT

inflate tires beyond

the maximum recommended pressure

printed on side of tire.

CLEANING

• Rinse inside of hopper and exterior of spreader and

dry off before storing.

LUBRICATE

(See figure 18.)

• Lightly apply automotive grease as needed to the

sprocket and gear.

• Oil the nylon bushings on the vertical sprocket shaft

and on the axle at least once a year, or more often as

needed.

• Oil right hand (idler) wheel bearing at least once a

year or more often as needed.

GREASE

OIL

OIL