18

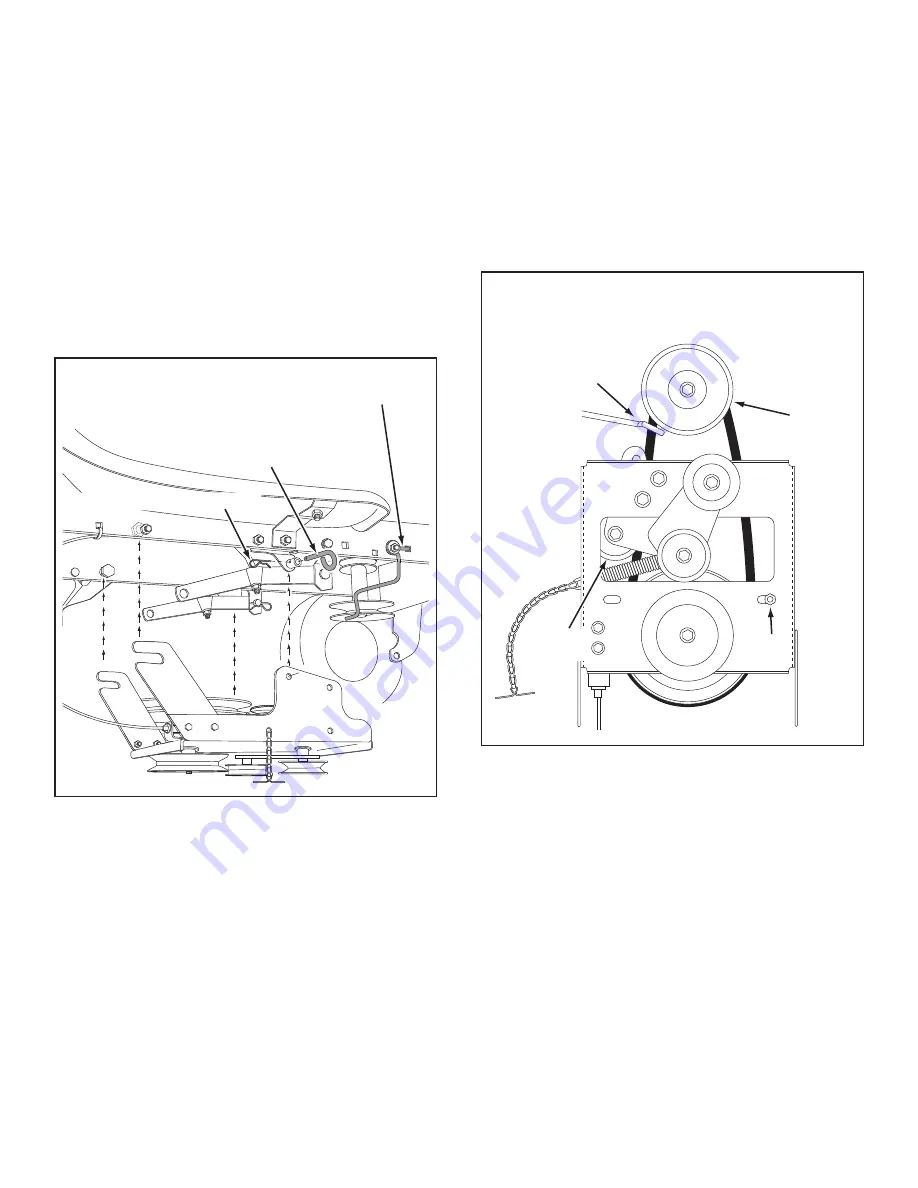

FIGURE 40

VIEWED FROM UNDERNEATH

FIGURE 39

STEP 40: (SEE FIGURE 40)

• Assemble the short "V" belt onto the engine pulley

and then onto the large pulley on top of the clutch/idler

assembly. The belt must be placed to the inside of the

engine pulley keeper, the idler pulley and the keeper

bolt located beside the large pulley.

IMPORTANT:

Do Not

assemble the "V" belt around the

outside of the engine pulley keeper or the keeper bolt.

•

Go to step 48 on page 21.

STEP 39: (SEE FIGURE 39)

• Remove the engine pulley keeper from the side of

the tractor frame by removing the washer and nut

that secure the keeper. Attach the new pulley keeper

supplied with the snow thrower, reusing the original

bolt, washer and nut.

NOTE:

Some tractors may already be equipped with a

pulley keeper that is identical to the new one supplied.

• Attach the clutch/idler assembly to the tractor frame

as follows. Hook the assembly's notched arms onto

the two shoulder bolts you assembled to the inside

of the tractor frame. Lift the front of the assembly and

attach it to the R.H. and L.H. hanger brackets using

two pivot lock pins (MM) and 1/8" hairpin cotters (KK).

NEW ENGINE PULLEY KEEPER WITH

ORIGINAL BOLT, NUT AND WASHER

PIVOT LOCK PIN (MM)

(use second hole)

1/8" HAIRPIN COTTER (KK)

ENGINE

PULLEY

KEEPER BOLT

IDLER

PULLEY

ENGINE

PULLEY

KEEPER

Left Side

of Tractor

CLUTCH/IDLER ASSEMBLY

Summary of Contents for 486.248381

Page 31: ...31 NOTES ...

Page 32: ...32 NOTES ...

Page 33: ...33 NOTES ...

Page 34: ...34 PARTS REPAIR PARTS FOR MODEL 486 248381 42 SNOW THROWER ...