4

OPERATION

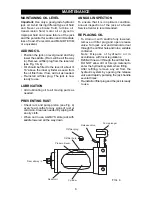

FIG. 3

KNOW YOUR JACK

Compare Fig. 3 illustration with your jack

BEFORE operation to become familiar with

the location of various jack components.

BEFORE USE

• Read the operator's manual completely

and familiarize yourself thoroughly with the

product, its components and recognize the

hazards associated with its use.

• Occasionally during shipment and/or

handling air can get trapped in the system,

which can interfere with the jacks lifting

performance.

• It is recommended to cycle the jack a few

times without applying load:

• Close release valve by turning the jack

handle clockwise until tight.

• Pump the handle until the jack saddle

reaches its maximum height.

• Open release valve by turning jack handle

counterclockwise, but no more than 1/2

full turn. Allow the saddle to reach its

lowest position.

• Repeat the above procedure a few times.

• To release air from the hydraulic system:

• Open the release valve by turning the jack

handle counterclockwise, but never by

more than 1/2 full turn.

• Remove the oil filler plug from the cylinder.

(see Fig. 4)

• Rapidly pump jack handle through several

full strokes.

• Reinstall the oil filler plug into the cylinder

again and jack is now ready to use.

Jack Handle

Handle

Socket

Rear Caster

Front Wheel

Lifting Arm

Oil Filler Plug

(Not Shown, on Reservoir)

Saddle

Release Valve

SPECIFICATIONS

Rated Capacity: 3 Ton / 6000 Lbs

Jack Dimensions: 25” x 13 7/16” x 6 7/16”

Lifting Range: 5 1/2” - 19”

(140mm - 483mm)

Oil Capacity: 150 c.c.

Net Weight: 80.7 Lbs