Summary of Contents for 917.254244

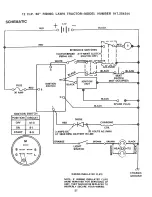

Page 28: ...T n LLI rn Z I ILl I Q 0 i D I J z wl n co n 3 qp m I IJJ LU i _ IlL 28 t_ T_ ...

Page 30: ...a _ w z ft w 30 ...

Page 31: ... D iii iii Z J I 0 F z z CO LU I 0 J _J z iii F Q E W _d D LU F D _z 0 31 ...

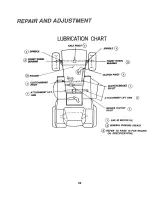

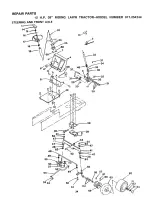

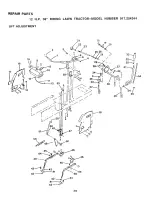

Page 34: ...REPAIR PARTS 12 H P 38 RIDING LAWN TRACTOR MODEL NUMBER 917 254244 I ...