Summary of Contents for 917.270533

Page 30: ...SERVICE NOTES 3O ...

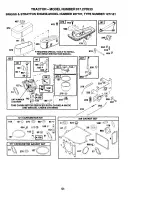

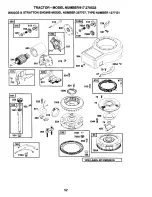

Page 40: ...ENGINE TRACTOR MODEL NUMBER 917 27053 4O 33 29 40 ...

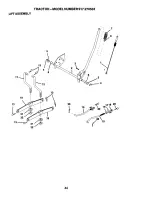

Page 44: ...TRACTOR MODEL NUMBER 917 270533 LIFTASSEMBLY 13 5 4 6 2 3 6 5 19 13 31 32 13 19 2O 2O 15 44 ...

Page 46: ...MOWER DECK TRACTOR MODEL NUMBER 917 270533 34 148 21 2 21 28 29 22 24 25 26 27 46 ...