Summary of Contents for 917.271121

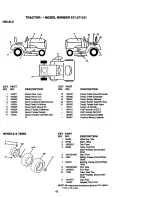

Page 34: ...ELECTRICAL TRACTOR MODEL NUMBER 917 271121 I i 34 ...

Page 36: ...TRACTOR MODEL NUMBER 917 271121 CHASSIS AND ENCLOSURES 28 58 12 14 11 4 3 3 74 3 51 36 ...

Page 38: ...TRACTOR MODEL NUMBER 917 271121 GROUND DRIVE 62 146 27 77 100 H 38 ...

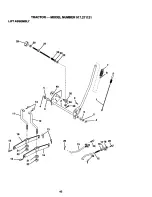

Page 40: ...TRACTOR MODEL NUMBER 917 271121 STEERING ASSEMBLY _M _41 I 62 44 47 67 15 4O ...

Page 42: ...ENGINE TRACTOR MODEL NUMBER 917 271121 t 8O 33 33 29 _OPTIONAL EQUIPMENT 42 ...

Page 58: ...58 ...