Summary of Contents for 917.273280

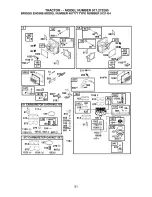

Page 32: ...TRACTOR MODEL NUMBER 917 273280 ELECTRICAL I I 42 41 79 I I I I I 26 40 33 25 29 I I I I I 32 ...

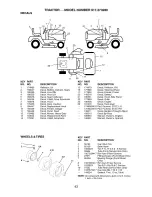

Page 44: ...TRACTOR MODEL NUMBER 917 273280 LIFT ASSEMBLY 38 40 6 3 2 6 7 51 44 ...

Page 46: ...TRACTOR MODEL NUMBER 917 273280 MOWER DECK 112 21 5 46 114 49 130 4_ 2 _37 33 121 21 1 18 46 ...