Summary of Contents for 917.273860

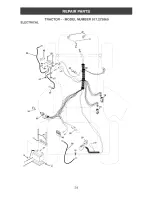

Page 34: ...ELECTFlmCAL TRACTOR o o MODEL NUMBER 917 273860 I 25 i 11 1_ i I _ l I I i 34 ...

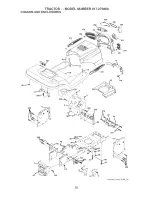

Page 38: ...TRACTOR MODEL NUMBER 917 273860 GROUND DRWE 3O _ I 70 116 36 73 drive hydro stit29 38 ...

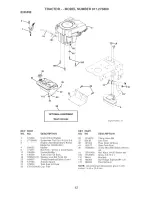

Page 54: ...TRACTOR o o MODEL NUMBER 917 273860 KOHLER ENGmNE MODEL NUMBER SV600_TYPE NUMBER 0001 t5 54 ...

Page 58: ...58 ...