Summary of Contents for 917.275012

Page 7: ..._Drain_ Video Cassette Video Cassette For Future Use Slope Sheet Keys 2 Keys Slope Sheet 7 ...

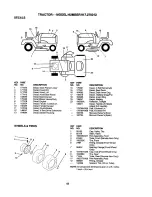

Page 34: ...TRACTOR MODEL NUMBER 917 275012 ELECTRICAL 22 26 29 P 33 _30 r ...

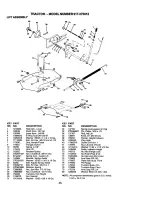

Page 38: ...TRACTOR MODEL NUMBER 917 275012 GROUND DRIVE 28 9 7 15 47 69 62 4 38 ...

Page 46: ...TRACTOR MODEL NUMBER 917 275012 MOWER DECK 46 I 130 49 I 46 i I ii 116 11 19 1 17 26 46 ...

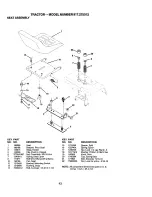

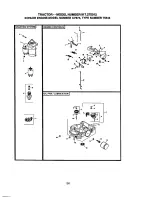

Page 48: ...TRACTOR o MODEL NUMBER 917 275012 TRANSAXLE 48 ...

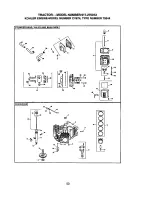

Page 58: ...58 ...