Summary of Contents for 917.275022

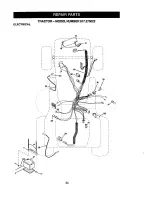

Page 34: ...TRACTOR MODEL NUMBER 917 275022 ELECTRICAL 22 34 ...

Page 40: ...TRACTOR MODEL NUMBER 917 275022 STEERING 15 13 47 1313 4O ...

Page 46: ...TRACTOR MODEL NUMBER 917 275022 MOWER DECK 46 45 31 42 21 _ 46 116 17 24 26 46 ...

Page 48: ...TRACTOR MODEL NUMBER 917 275022 TRANSAXLE MODEL NUMBER 331 3000 i I I 48 ...

Page 58: ...58 ...