12- ENG

D29783

1. Dried material is

clogging side-

port “A” and

causing side-port

“B” to blow spray

towards the

clogged side.

1. Soak side-ports in thinner to

clean clog.

DO NOT

poke any

opening with hard objects.

3. Air pressure too

high

Spitting, irregular or

fluttering spray

Split spray pattern

1. Air pressure too high.

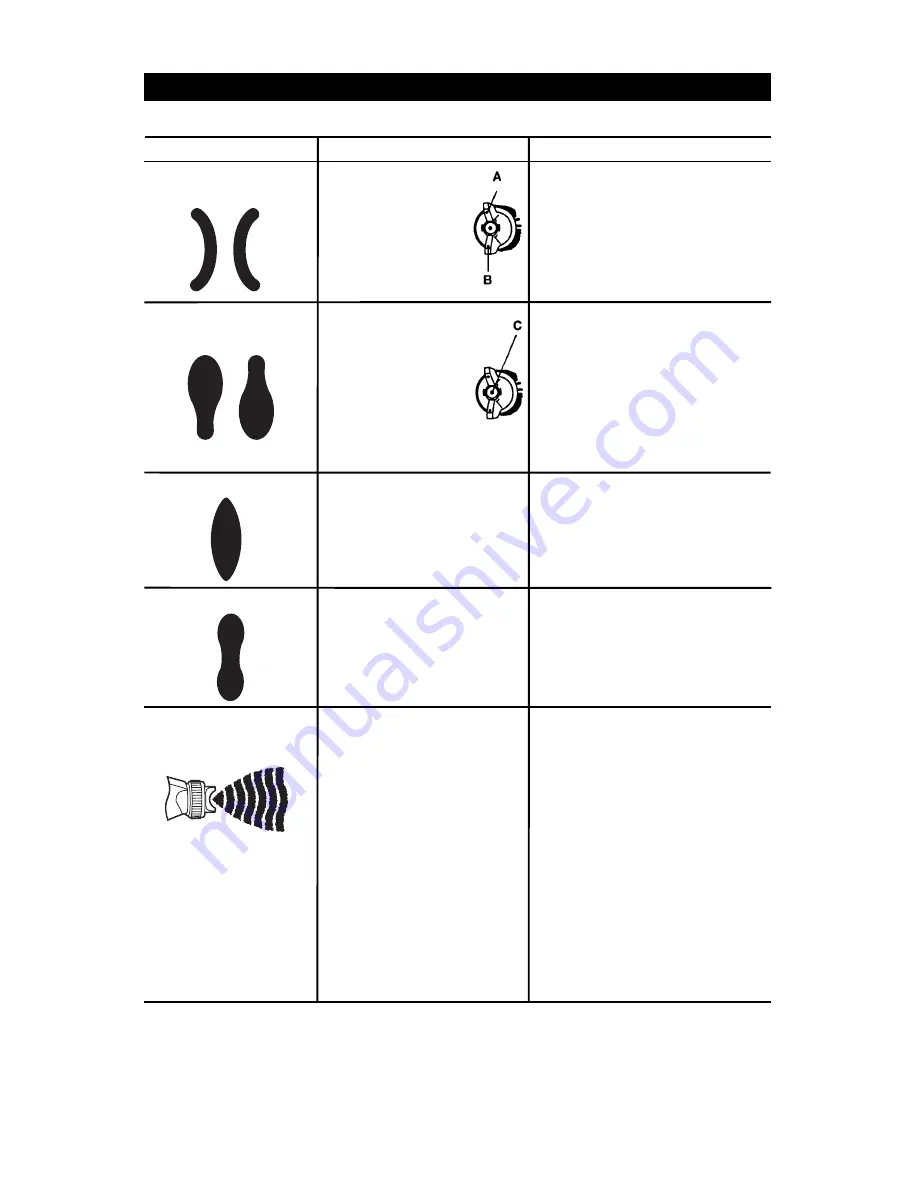

PROBLEM

CORRECTION

TROUBLESHOOTING

NOTICE:

See parts list to identify parts referred to in these Troubleshooting steps.

CAUSE

Heavy right or left side

pattern

Heavy top or bottom

pattern

1. Dried material at

fluid nozzle “C”

restricts air flow.

2. Loose air

nozzle.

3. Turn pattern control knob

clockwise to reduce air

pressure.

1. Remove air nozzle. Wipe fluid

tip using a cloth soaked in a

suitable solvent or a soft brush.

2. Fasten nozzle securely.

Heavy center pattern

1. Too much material.

2. Material too thick.

1. Turn fluid control knob

clockwise to decrease material

flow or turn pattern control

knob counter clockwise to

increase air pressure.

2. Thin material.

1. Turn pattern control knob

clockwise to reduce air

pressure.

1. Leak at thread of fluid

nozzle.

1. Tighten fluid nozzle.

2. Leak at fluid needle.

2. Tighten the fluid needle

adjustment nut.

3. Insufficient fluid in cup.

3. Fill cup with fluid.

4. Vent hole in material cup

cover clogged (only in

siphon feed mode).

4. Clean vent hole.

2. Not enough material

2. Turn fluid control knob counter

clockwise to increase material

flow.

5. Material cup tilted at an

excessive angle.

5. Do not tilt material cup

excessively or rotate fluid tube.

6. Fluid too heavy for siphon

feed.

6. Thin material or convert to

remote pressure feed mode.

7. Loose fluid tip or damaged

tip seat

7. Tighten or replace.

Summary of Contents for 919.155190

Page 27: ...27 SP D29783 NOTES ...

Page 28: ...28 SP D29783 NOTES ...

Page 29: ...29 SP D29783 NOTES ...

Page 30: ...30 SP D29783 NOTES ...

Page 31: ...31 SP D29783 NOTES ...