10

➀

Wheel

adjuster (on

each wheel)

➁

Engine oil

➀

Rear door

hinge

➀

Handle bracket mounting pins

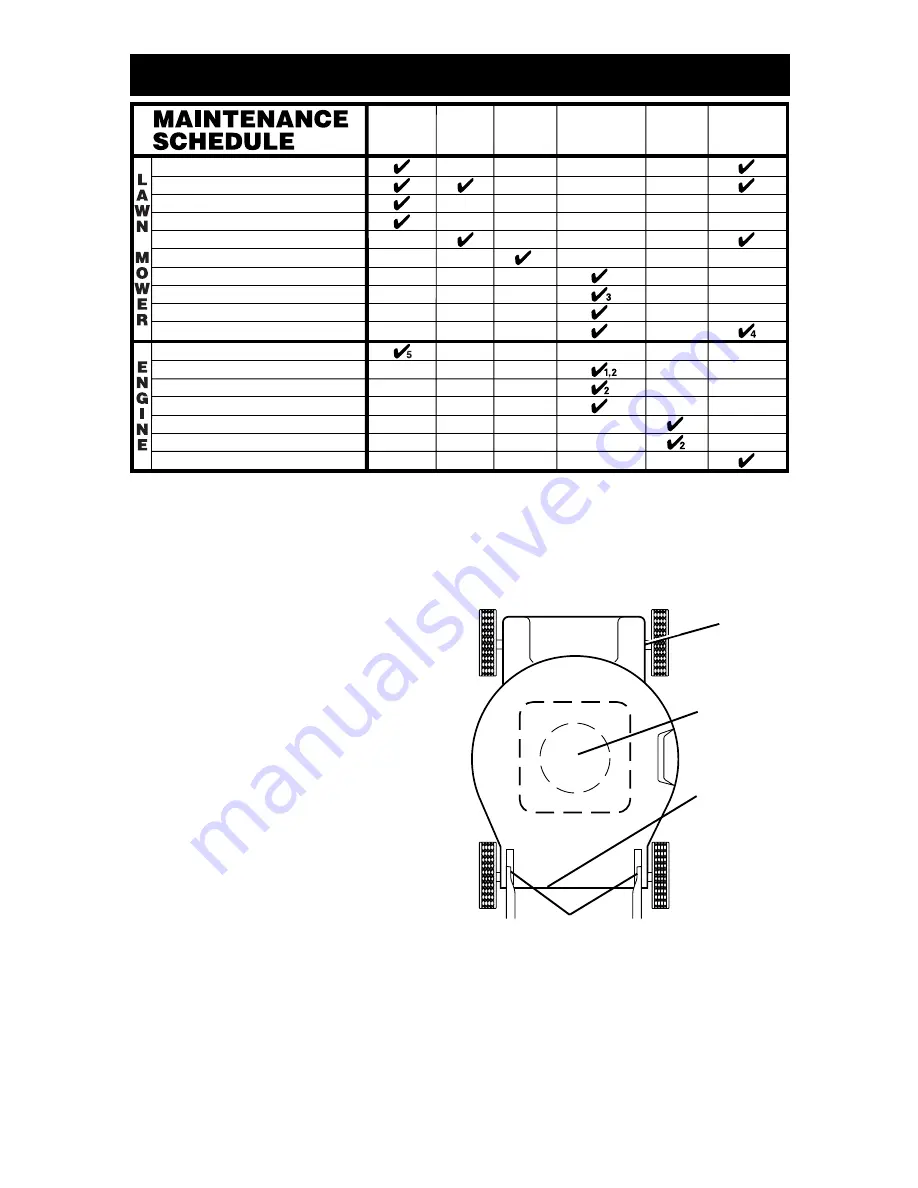

Check for Loose Fasteners

Clean / Inspect Grass Catcher *

Check Tires

Check Drive Wheels ***

Clean Lawn Mower ****

Clean under Drive Cover ***

Check Drive Belt / Pulleys ***

Check / Sharpen / Replace Blade

Lubrication

Clean and Recharge Battery **

Check Engine Oil level

Change Engine Oil

Clean Air Filter

Inspect Muffler

Replace Spark Plug

Replace Air Filter Paper Cartridge

Empty fuel system or add Stabilizer

BEFORE

EACH

USE

AFTER

EACH

USE

EVERY

10

HOURS

EVERY

25 HOURS

OR SEASON

EVERY

100

HOURS

BEFORE

STORAGE

1

- Change more often if operating under a heavy load or in high outdoor temperatures.

2

- Service more often if operating in dirty or dusty conditions.

3

- Replace blades more often when mowing in sandy soil.

4

- Charge 48 hours at end of season.

5

- And after each 5 hours of use.

(if so equipped)

Electric-Start mowers

Power-Propelled mowers

Use a scraper

to clean under deck

*

**

***

****

MAINTENANCE

GENERAL REC OM MEN DA TIONS

The warranty on this lawn mower does not

cover items that have been sub ject ed to

operator abuse or negligence. To receive

full value from the warranty, operator must

maintain unit as in struct ed in this manual.

Some adjustments will need to be made

periodically to properly maintain your unit.

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Ad just ments

section of this manual.

• At least once a year, replace the spark

plug, clean or replace air fi lter element

and check blade for wear. A new spark

plug and clean/new air fi lter element

assure proper air-fuel mix ture and help

your engine run bet ter and last longer.

• Follow the maintenance schedule in this

manual.

BEFORE EACH USE

• Check engine oil level.

• Check for loose fasteners.

LUBRICATION

Keep unit well lubricated

(See “LU BRI CA TION CHART”).

LUBRICATION CHART

➀

Spray lubricant

➁

See "ENGINE" in Maintenance section.

IMPORTANT: Do not oil or grease plastic

wheel bearings. Viscous lu

bri cants will

attract dust and dirt that will short en the life of

the self-lu bri cat ing bearings. If you feel they

must be lu bri cated, use only a dry, pow dered

graphite type lubricant spar ingly.