English

6

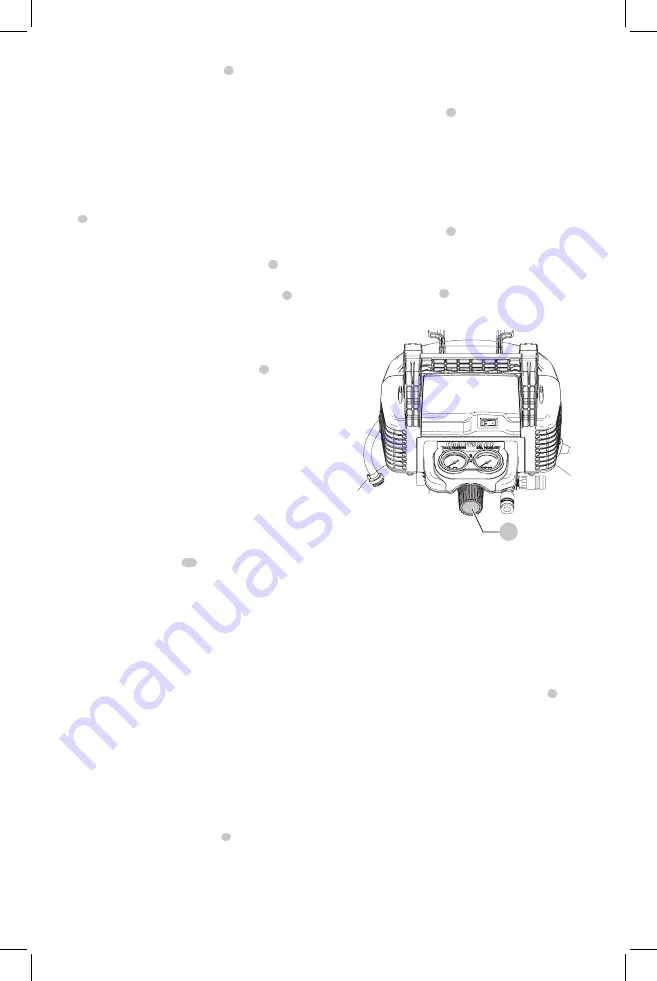

On(i)/Off(O) switch:

Place this switch

4

in the On(I)

position to provide automatic power to the pressure switch

and Off(O) to remove power at the end of each use.

Pressure switch (not shown):

The pressure switch

automatically starts the motor when the air tank pressure

drops below the factory set “cut-in” pressure. It stops the

motor when the air tank pressure reaches the factory set

“cut-out” pressure.

safety Valve:

If the pressure switch does not shut off the

air compressor at its “cut-out” pressure setting, the safety

valve

8

will protect against high pressure by “popping out”

at its factory set pressure (slightly higher than the pressure

switch “cut-out” setting).

Tank Pressure gauge:

The tank pressure gauge

5

indicates the reserve air pressure in the tank.

Outlet Pressure gauge:

The outlet pressure gauge

9

indicates the air pressure available at the outlet side of the

regulator. This pressure is controlled by the regulator and is

always less than or equal to the tank pressure.

Regulator:

Controls the air pressure shown on

the outlet pressure gauge. Turn regulator knob

7

clockwise to increase pressure and counterclockwise to

decrease pressure.

Cooling system (not shown):

This compressor contains

an advanced design cooling system. At the heart of this

cooling system is an engineered fan. It is perfectly normal

for this fan to blow air through the vent holes in large

amounts. You know that the cooling system is working

when air is being expelled.

Air Compressor Pump (not shown):

Compresses air into

the air tank. Working air is not available until the compressor

has raised the air tank pressure above that required at the

air outlet.

Drain Valve:

The drain valve

10

is located at the base of

the air tank and is used to drain condensation at the end of

each use.

Check Valve (not shown):

When the air compressor is

operating, the check valve is “open”, allowing compressed

air to enter the air tank. When the air compressor reaches

“cut-out” pressure, the check valve “closes”, allowing air

pressure to remain inside the air tank.

Motor Overload Protector (not shown):

The motor has

a thermal overload protector. If the motor overheats for

any reason, the overload protector will shut off the motor.

The motor must be allowed to cool down before restarting.

To restart:

1. Set the On/Off switch to “Off” and unplug unit.

2. Allow the motor to cool.

3. Plug the power cord into the correct branch

circuit receptacle.

4. Set the On/Off switch to “On” position.

Quick Connects :

The quick connects

6

accepts industrial

quick connect plugs. The two quick connect bodies allow

the use of two tools at the same time.

How to Use Your Unit (Fig. A, B)

How to Stop

1. Set the On/Off switch

4

to “Off”.

2. Unplug unit when not in use.

Before Starting

WARNING:

Do not operate this unit until

you read this instruction manual for safety,

operation and maintenance instructions.

Before Each Start-Up

1. Set the On/Off switch

4

to “Off”.

2. Plug the power cord into the correct branch circuit

receptacle. (Refer to

Voltage and Circuit Protection

paragraph in the

installation

section of this manual.)

3. Turn regulator knob

7

counterclockwise until fully

closed. Ensure regulated pressure gauge reads 0 PSI

(0 kPa).

Fig. B

7

4. Attach hose and accessories.

5. Ensure all covers and labels are in place, legible (for

labels) and securely mounted. Do not use compressor

until all items have been verified.

WARNING:

Risk of unsafe operation. Firmly grasp

air hose in hand when installing or disconnecting

to prevent hose whip.

WARNING:

Risk of unsafe operation. Do not use

damaged or worn accessories

.

nOTE:

This unit is equipped with quick connects

6

. The

hose or accessory being connected will require a quick

connect plug.

WARNING:

Risk of Bursting. Too much air pressure

causes a hazardous risk of bursting. Check the

manufacturer’s maximum pressure rating for air

tools and accessories. The regulator outlet pressure

must never exceed the maximum pressure rating.

NOTICE:

Risk of property damage. Compressed air

from the unit may contain wa ter condensation and

oil mist. Do not spray un fil tered air at an item that

could be damaged by moisture. Some air tools and

accessories may require filtered air. Read the

in struc tions for the air tools and accessories.