11

E

Checking Laser Accuracy

The laser tools are sealed and calibrated at the factory.

It is recommended that you perform an accuracy check

prior to using the laser for the first time

(in case the

laser was exposed to extreme temperatures) and then

regularly to ensure the accuracy of your work.

When

performing any of the accuracy checks listed in this

manual, follow these guidelines:

• Use the largest area/distance possible, closest to the

operating distance. The greater the area/distance, the

easier to measure the accuracy of the laser.

• Place the laser on a smooth, flat, stable surface that

is level in both directions.

• Mark the center of the laser beam.

Horizontal Beam - Scan Direction

Checking the horizontal scan calibration of the laser

requires two walls at least 30’ (9m) apart. It is important

to conduct a calibration check using a distance no

shorter than the distance of the applications for which

the tool will be used.

1.

Place the back of the laser against a wall and facing

straight ahead toward the opposing wall (Figure

D

1

).

2.

Move the Power/Transport Lock switch to the right

(Figure

A

3

) to turn the laser ON in self-leveling

mode and display the horizontal and vertical beams.

3.

Turn the laser 45º counter-clockwise so that the

right-most end of the laser line is displayed on the

wall.

4.

Mark

a

on the center of the beam on the wall.

5.

Turn the laser 90º clockwise so that the left-most

end of the laser line is displayed near

a

(Figure

D

2

).

6.

Mark

b

on the center of the beam on the wall.

7.

Measure the vertical distance between

a

and

b

.

8.

If your measurement is greater than the

Allowable

Distance Between

a

and

b

for the corresponding

Distance Between Walls

in the following table, the

laser must be serviced at an authorized service

center.

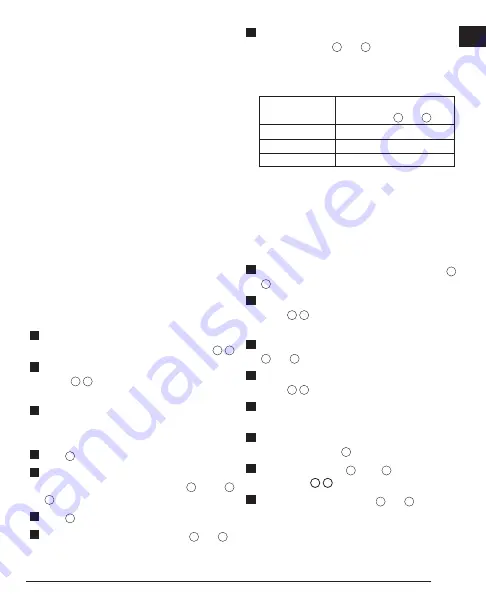

Distance

Between Walls

Allowable Distance

Between

a

and

b

30’ (9m)

15/32” (12mm)

40’ (12m)

9/16” (14.4mm)

50’ (15m)

23/32” (18mm)

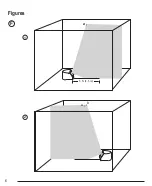

Horizontal Beam - Pitch Direction

Checking the horizontal pitch calibration of the

laser requires a single wall at least 30’ (9m) long.

It is important to conduct a calibration check using

a distance no shorter than the distance of the

applications for which the tool will be used.

1.

Place the laser against the end of the wall (Figure

E

1

).

2.

Move the Power/Transport Lock switch to the right

(Figure

A

3

) to turn the laser ON in self-leveling

mode and display the horizontal and vertical beams.

3.

At least 30’ (9m) apart along the laser beam, mark

a

and

b

.

4.

Move the laser to the opposite end of the wall

(Figure

E

2

).

5.

Position the laser toward the first end of the same

wall and parallel to the adjacent wall.

6.

Adjust the height of the laser so the center of the

beam is aligned with

b

.

7.

Directly above or below

a

, mark

c

along the laser

beam (Figure

E

3

).

8.

Measure the distance between

a

and

c

.

Summary of Contents for CMHT77630

Page 2: ...A 1 2 4º _ 3 Figures 2 ...

Page 3: ...C B 1 4 20 3 ...

Page 4: ...D 1 2 Figures 4 45 90 a b 30 9m _ a ...

Page 5: ...1 2 3 5 E a b c b a b 30 9m _ a b ...

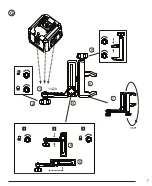

Page 6: ...1 2 Figures 6 F a 5 1 5 m a b ...

Page 7: ...7 1 4 20 360º 1 7 5 2 4 3 6 8 G ...

Page 32: ... 2019 CRAFTSMAN 701 East Joppa Road Towson MD 21286 N599505 January 2019 www CRAFTSMAN com ...