7

English

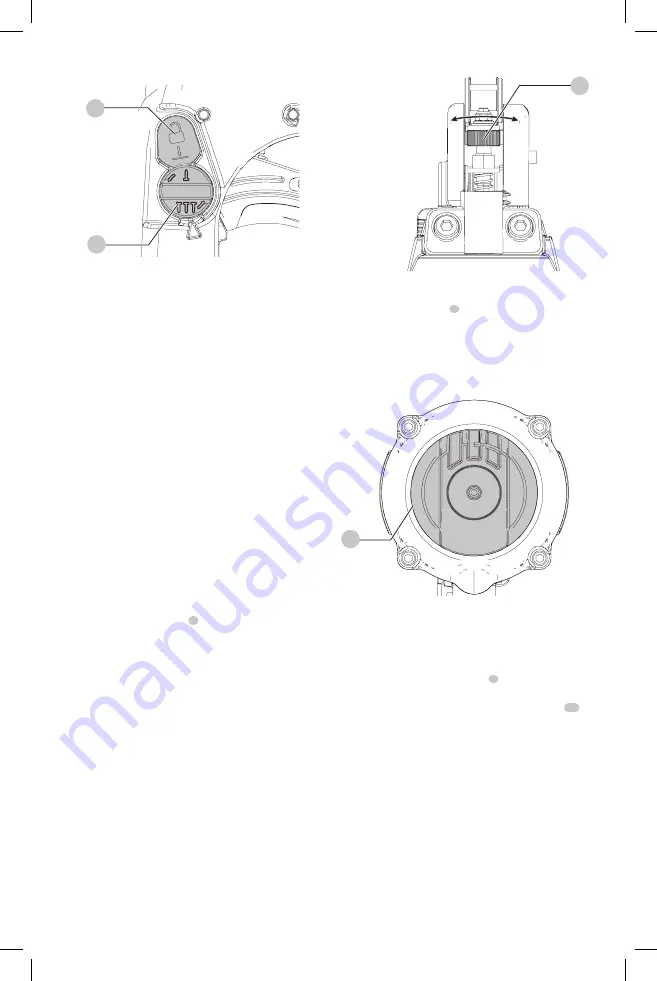

Fig. H

11

10

To Operate the Tool Using the single sequential

Actuation Trigger

1. Depress the contact trip against the work surface.

2. Pull the trigger to drive the fastener.

3. Allow the tool to recoil off the work surface.

WARNING:

A fastener will be driven each time the

trigger is pulled as long as the contact trip remains

depressed which could result in accidental driving.

To Operate the Tool Using the Contact Actuation

Method

1. Pull the trigger.

2. Depress the contact trip against the work surface. As

long as the trigger is pulled, the tool will drive a fastener

every time the contact trip is depressed. This allows the

user to rapidly drive multiple fasteners.

Adjusting Depth (Fig. I)

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove air supply before

making any adjustments or removing/installing

attachments or accessories.

An accidental

actuation can cause injury.

The depth that the fastener is driven can be adjusted using

the depth adjustment wheel

7

.

1. To drive the fastener shallower, rotate the depth

adjustment wheel to the right.

2. To drive a fastener deeper, rotate the depth adjustment

wheel to the left.

The adjustment knob has detents every full turn. Test drive

another fastener and check depth. Repeat as necessary to

achieve desired results. The amount of air pressure required

will vary depending on the size of the fastener and the

material being fastened.

Experiment with the air pressure setting to determine the

lowest setting that will consistently perform the job at hand.

CAUTION:

Air pressure in excess of that required can

cause premature wear and/or damage to the tool.

Fig. I

7

Directional Exhaust Deflector (Fig. J)

Adjust exhaust deflector

1

, so the exhaust air blast

will be directed away from the operator. The exhaust

deflector provides sixteen detented positions for directing

the exhaust blast away from the operator. Grasp the

deflector and rotate it to the desired position for the

current application.

Fig. J

1

No-Mar Pad (Fig. K, L)

WARNING:

Disconnect tool from air supply and

engage trigger lock, before removing or re-installing

no-mar pad.

The contact trip with no-mar pad

6

is provided to reduce

marring of the work surface. The no-mar pad can be

removed, and stored inside the end cap, magazine

15

, to

provide increased grip and depth-of-drive for toe-nailing

applications.