11

MAINTENANCE

WARNING:

To avoid serious personal injury, always stop

the engine and allow it to cool before cleaning or maintaining

the unit. Never perform cleaning or maintenance while the

unit is running. Disconnect the spark plug wire to prevent

the unit from starting accidentally.

WARNING:

Wear protective clothing and observe all

safety instructions to prevent serious personal injury.

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures, take the unit to

an authorized service dealer. Call

1-888-331-4569 for more

information.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by an authorized service

dealer. Call

1-888-331-4569 for more information.

NOTE: Please read the California/EPA statement that came with the

unit for a complete listing of terms and coverage for the

emissions control devices, such as the spark arrestor, muffler,

carburetor, etc.

FREQUENCY

MAINTENANCE REQUIRED

Every 10 hours

• Clean and re-oil the air filter. Refer to

Maintaining the Air Filter.

After the first

10 hours and

at 38 hours

• Change the oil. Refer to Changing the Oil.

• Have the rocker arm clearance checked by

an authorized service dealer.

• Check the spark plug condition and gap.

Refer to Maintaining the Spark Plug.

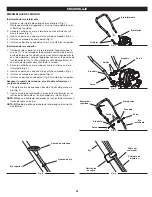

REPLACING THE EDGER BLADE

Removing the Edger Blade

1. Place a 15/16 in. wrench over the lock nut (Fig. 12).

2. Insert a 5/16 in. Allen wrench into the spindle hole (Fig. 12).

3. While hold ing the Allen wrench in place, loosen the lock nut by

turning it counterclock wise with the wrench (Fig. 12).

4. Remove the Allen wrench, wrench, lock nut and edger blade

(Fig. 13). Keep the lock nut for installing the new edger blade.

Installing the Edger Blade

1. Install the new edger blade and lock nut onto the output shaft

(Fig. 13). Make sure the blade edges are facing the correct

direction (Fig. 13). The unit will not function properly if the edger

blade is facing the wrong direction.

2. Place the wrench over the lock nut (Fig. 12).

3. Insert the Allen wrench into the spindle hole (Fig. 12).

4. While hold ing the Allen wrench in place, tighten the lock nut by

turning it clock wise with the wrench (Fig. 12). Make sure that the

edger blade stays flat and centered against the output shaft

while tightening the lock nut. Tighten the lock nut until the edger

blade is firmly secure.

5. Remove the wrench and Allen wrench.

Fig. 12

Spindle Hole

Allen Wrench

Wrench

Fig. 13

Lock Nut

Edger Blade

Blade Edges

Output Shaft

Loosen

Tighten

WARNING:

Make sure the blade is flat against the

output shaft bushing after the lock nut is tightened. If the

blade is off-cen ter, the unit will be dam aged by vibration,

and the blade may fly off, which can cause serious

personal in ju ry.