Summary of Contents for EZ3 917.271064

Page 34: ...ELECTRICAL TRACTOR MODEL NUMBER 917 271064 I t t 34 ...

Page 36: ...TRACTOR MODEL NUMBER 917 271064 CHASSIS AND ENCLOSURES 208 11 _ _ 54 74 1 ...

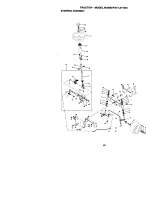

Page 38: ...TRACTOR MODEL NUMBER 917 271064 GROUND DRIVE 36 38 ...

Page 40: ...TRACTOR MODEL NUMBER 917 271064 STEERING ASSEMBLY _41 47 40 ...

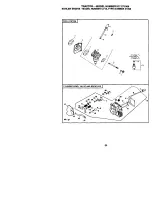

Page 42: ...ENGINE TRACTOR MODEL NUMBER 917 271964 14 _ i _ 105 42 ...

Page 46: ...TRACTOR MODEL NUMBER 917 271064 LIFTASSEMBLY I 6 5 20 15 _ _ 161_71_ 2_ _ 46 ...

Page 48: ...TRACTOR MODEL NUMBER 917 271064 MOWER DECK 34 119 118 16 1 19 13_ 10_ 9_ 27 48 ...

Page 58: ...58 ...