SAFETY INSTRUCTIONS

ASSEMBLY

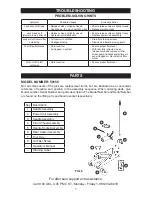

FIG. 1

FIG. 3

TO ASSEMBLE THE TWO PIECE

HANDLE

• Locate the spring pin on bottom end of upper

handle and the spring pin receiver on the

upper end of lower handle. (Fig. 1).

• Align the spring pin with the spring pin

receiver. Connect the two handle pieces

together by pressing the spring pin and

insert until the spring pin is locked in the

spring pin receiver.

TO ASSEMBLE THE HANDLE INTO

THE SOCKET

1. Press and hold the handle socket to loosen

the lock pin (Fig. 2).

2. Pull out the lock pin, then release handle

socket slowly.

Caution:

Handle socket is spring loaded.

Beware of pinching on fingers during

removal of lock pin.

3. Pull and hold the spring knob (Fig. 3).

4. Insert the assembled handle into the

socket, until it is firmly seated.

5. Release spring knob to secure the handle

in position.

Upper Handle

Handle Socket

Assembled

Handle

Lower Handle

!

3

WARNING

• Study, understand, and follow all

instructions with and on this device

before operating this device.

• Do not exceed rated capacity.

• Use only on hard, level surface.

• This is a lifting device only. Immediately

after lifting, support the vehicle with

appropriately rated vehicle stands.

• Do not move or dolly the vehicle while

on the jack.

• Failure to heed product markings or

warnings may result in personal injury

or property damage.

Spring Pin

Spring Knob

Spring Pin Receiver

To avoid crushing and

related injuries:

N E V E R w o r k o n ,

under or around a load

supported only by jack.

ALWAYS use adequately

rated jack stands.

!

WARNING

! SAFETY MESSAGE !

Be sure all tools and personnel are clear

before lowering load. No alterations

shall be made to this product. Only

attachments and/or adapters supplied by

the manufacturer shall be used. Lift only

on areas of the vehicle as specified by the

vehicle manufacturer.

NOTE:

Jack stands are rated per pair

unless otherwise noted.

Use 1 matched pair per vehicle only.

!

ADVERTENCIA

Leer, comprender, y seguir las instrucciones

antes de utilizar el aparato. El manual

de instrucciones y la informacion de

seguridad deben estar comunicado en

lengua del operador antes del uso. No

seguir estas indicaciones puede causar

danos personales o materiales.

!

FIG. 2

Handle Socket

Lock Pin (to hold the

position of Handle

Socket in packaging)

1

2