Page 7

OPERATION

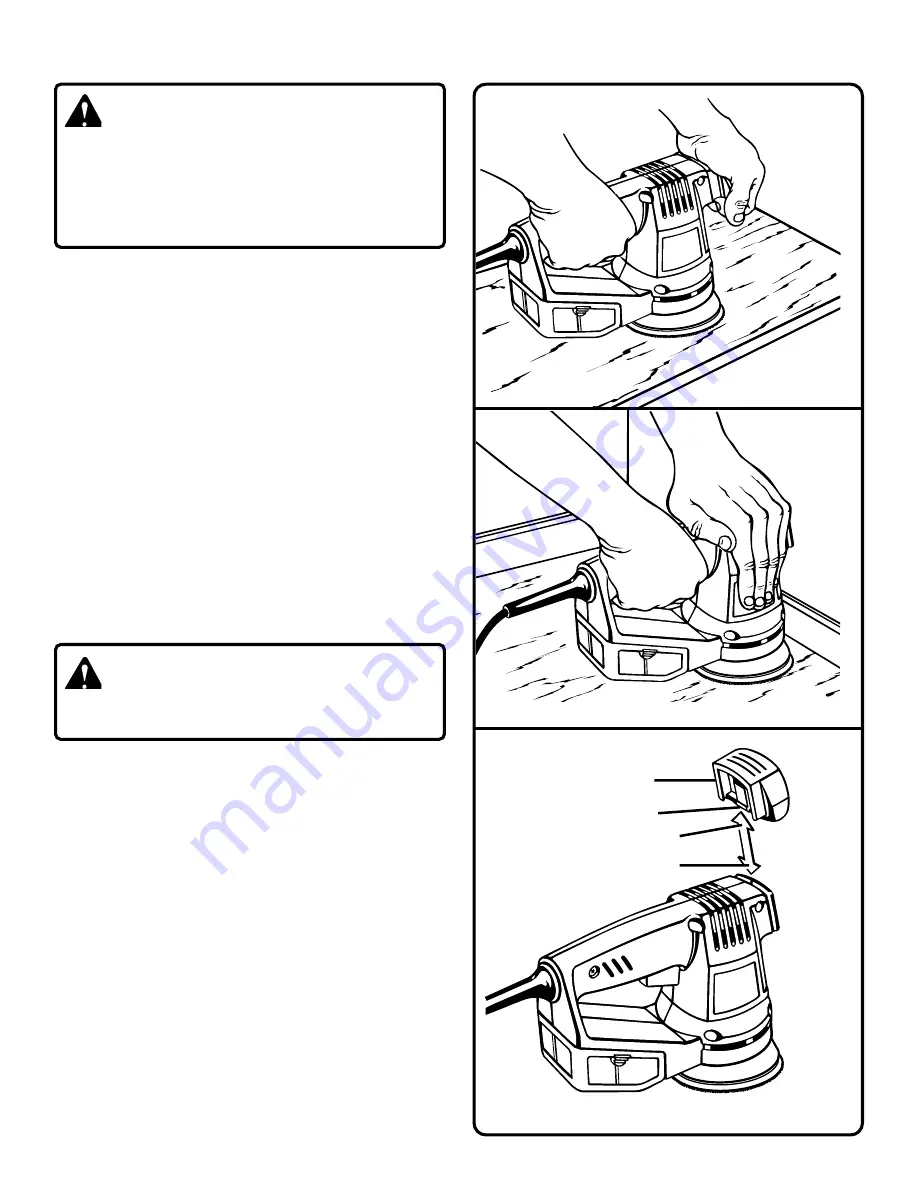

Fig. 6

Fig. 5

Fig. 4

APPLICATIONS

(Use only for the purposes listed below)

1. Sanding on wood surfaces.

2. Removing rust from and sanding steel surfaces.

PREPARING FOR OPERATION

For ease of operation, your sander has both a front handle

and rear handle.

See Figure 4.

This provides for two-hand

operation, which is necessary in order to maintain proper

control of your sander and keep both hands clear of the

sanding disc and sanding area. When operating your sander,

always use both hands.

See Figures 4 and 5.

Flush sanding can be performed with your sander when the

front handle is removed from sander.

See Figure 5.

Remove front handle by depressing tab under front handle

while pulling handle up and off of sander.

See Figure 6.

SANDING

Clamp or otherwise secure the work to prevent it from moving

under your sander.

WARNING:

Before connecting your sander to power supply source,

always check to be sure it is not in "Lock-on" position

(depress and release switch trigger). Failure to do so

could result in accidental starting of sander resulting in

possible serious injury. Also, do not lock the trigger on

jobs where your sander may need to be stopped suddenly.

WARNING:

Unsecured work could be thrown towards the operator

causing injury.

Place sander on workpiece so that all of sanding disc surface

is in contact with workpiece. Start your sander and move it

slowly over workpiece making successive passes in parallel

lines, circles, or crosswise movements. Upon completion of

sanding operation, turn sander off and wait until sanding disc

comes to a complete stop before removing from workpiece.

DO NOT FORCE.

The weight of the unit supplies adequate

pressure, so let the sanding disc and sander do the work.

Applying additional pressure only slows the motor, rapidly

wears sanding disc and greatly reduces sander speed.

Excessive pressure will overload the motor causing possible

damage from motor overheating and can result in inferior

work. Any finish or resin on wood may soften from the

frictional heat. Do not allow sanding on one spot too long as

the sander's rapid action may remove too much material,

making the surface uneven.

Extended periods of sanding as shown in Figure 5 may tend

to overheat the motor. If this occurs, turn sander off and wait

until sanding disc comes to a complete stop, then remove it

from workpiece. Remove your hand from vent area, turn

sander on and run it free without a load to cool motor.

TAB

TO REMOVE

TO INSTALL

FRONT

HANDLE

Summary of Contents for sears 315.277170

Page 12: ...QUARK BACK PAGE ...