6

STARTING/ STOPPING INSTRUCTIONS

USING THE ELECTRIC STARTER OR POWER START BIT

ACCESSORY TO START UNIT

NOTE:

This Unit Can Use an Power Start or Power Start Bit Optional

Accessory!

Please refer to the Power Starter or Power Start Bit operator’s

manual for proper use of these features. (Items may be Sold

Separately! Please refer to page 8 of this manual for more

information about purchasing these accessories.)

STARTING INSTRUCTIONS

1. Mix fuel with oil. See Oil and Fuel Mixing Instructions.

2. Fill the fuel tank with fresh, clean fuel mix. Refer to Fueling the Unit.

NOTE:

There is no need to turn the unit on. The On/Off Control is in the

ON ( I ) position at all times (Fig. 8).

3. Fully press and release the primer bulb 10 times, slowly. Some amount of

fuel should be visible in the primer bulb (Fig. 9). If fuel cannot be seen in

the bulb, press and release the bulb until fuel is visible.

4.

Flip the choke lever clockwise until it clicks (Fig. 7).

5. Crouch in the starting position (Fig. 8). Do not squeeze the throttle. Place

the Plug-In Power Start or Power Bit Start into the back of the unit. Refer

to the Operation section of the Plug-In Power Start or Power Bit Start

operator’s manual.

6. Press and hold the ON (I) button of the Plug-in Power Start or Power Bit

Start equipped drill in intervals no longer than 4 seconds each until the

unit starts.

7. Wait and allow the unit to idle for 5 - 10 seconds. If the unit stops running

during this time, squeeze the throttle control, then press and hold the ON

(I) button of the Plug-in Power Start or Power Bit Start equipped drill in

intervals no longer than 4 seconds each until the unit starts.

8. Remove the Plug-In Power Start or drill from the unit.

9. Squeeze and hold the throttle control for 30 to 60 seconds to allow the

unit to warm up.

IF...

The engine does not start, go back to step 3.

IF...

The engine fails to start after a few attempts, squeeze the throttle

control, then press and hold the Plug-In Power Start or drill ON

(I) button in intervals no longer than 4 seconds each until the unit

starts.

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to cool down by idling.

2. Press and hold the On/Off Control switch in the OFF (O) position until the

unit comes to a complete stop (Fig. 8).

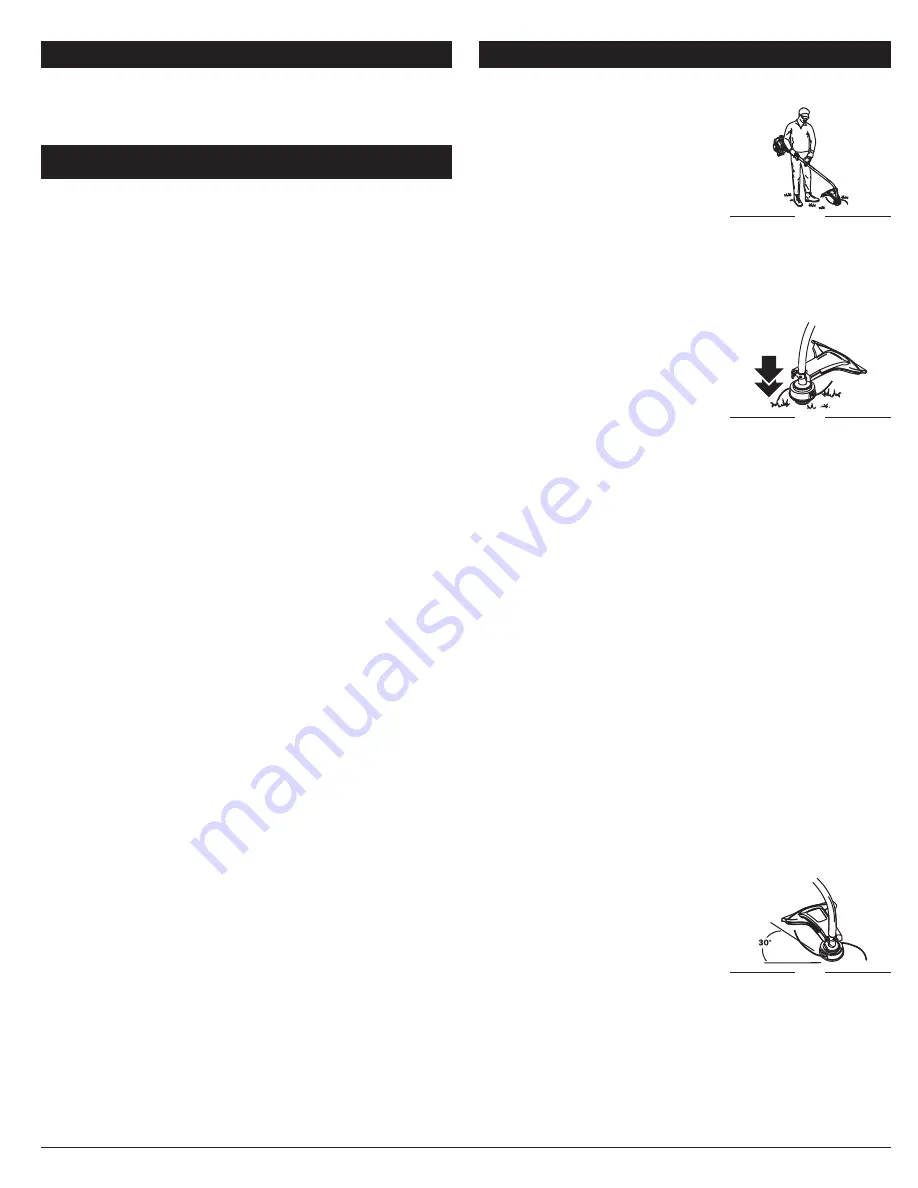

HOLDING THE UNIT

Before operating the unit, stand in the operating position (Fig. 11). Check for

the following:

•

The operator is wearing eye protection

and proper clothing

•

With a slightly-bent right arm, the

operator’s hand is holding the shaft grip

•

The operator’s left arm is straight, the left

hand holding the D-handle

•

The unit is at waist level

•

The cutting head is parallel to the ground

and easily contacts the grass without the need to bend over

ADJUSTING TRIMMING LINE LENGTH

The Bump Head™ cutting head allows the release of trimming line without

stopping the engine. To release more line, lightly tap the cutting head on the

ground (Fig. 12) while operating the unit at high speed.

NOTE:

Always keep the trimming line fully

extended. Line release becomes

more diffi cult when the cutting line

gets shorter.

Each time the head is bumped, about 1 inch

(25.4 mm) of trimming line releases. A blade in

the cutting head shield will cut the line to the

proper length if any excess line is released.

For best results, tap the bump knob on

bare ground or hard soil. If attempting a line

release in tall grass, the engine may stall. Always keep the trimming line fully

extended. Line release becomes more diffi cult when the cutting line gets

shorter.

NOTE:

Do not rest the Bump Head™ on the ground while the unit is

running.

Some line breakage will occur from:

•

Entanglement with foreign matter

•

Normal line fatigue

•

Attempting to cut thick, stalky weeds

•

Forcing the line into objects such as walls or fence posts

TIPS FOR BEST TRIMMING RESULTS

•

Keep the cutting head parallel to the ground.

•

Do not force the cutting head. Allow the tip of the line to do the cutting,

especially along walls. Cutting with more than the tip will reduce cutting

effi ciency and may overload the engine.

•

Cut grass over 8 inches (200 mm) by working from top to bottom in small

increments to avoid premature line wear or engine drag.

•

Cut from right to left whenever possible. Cutting to the left improves the

unit’s cutting effi ciency. Clippings are thrown away from the operator.

•

Slowly move the unit into and out of the cutting area at the desired

height. Move either in a forward-backward or side-to-side motion.

Cutting shorter lengths produces the best results.

•

Trim only when grass and weeds are dry.

•

The life of the cutting line is dependent upon:

•

Following the trimming techniques

•

What vegetation is being cut

•

Where vegetation is cut

For example, the line will wear faster when trimming against a foundation

wall as opposed to trimming around a tree.

DECORATIVE TRIMMING

Decorative trimming is accomplished by

removing all vegetation around trees, posts,

fences, etc..

Rotate the whole unit so that the cutting head

is at a 30° angle to the ground (Fig. 13).

OPERATING INSTRUCTIONS

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to cool down by idling.

2. Press and hold the On/Off Control switch in the

OFF (O)

position until the

unit comes to a complete stop (Fig. 8).

Fig. 11

Fig. 12

Fig. 13

Summary of Contents for WEEDWACKER INCREDI.PULL 316.791020

Page 21: ...21 NOTAS ...