DIAGONAL STRETCHING:

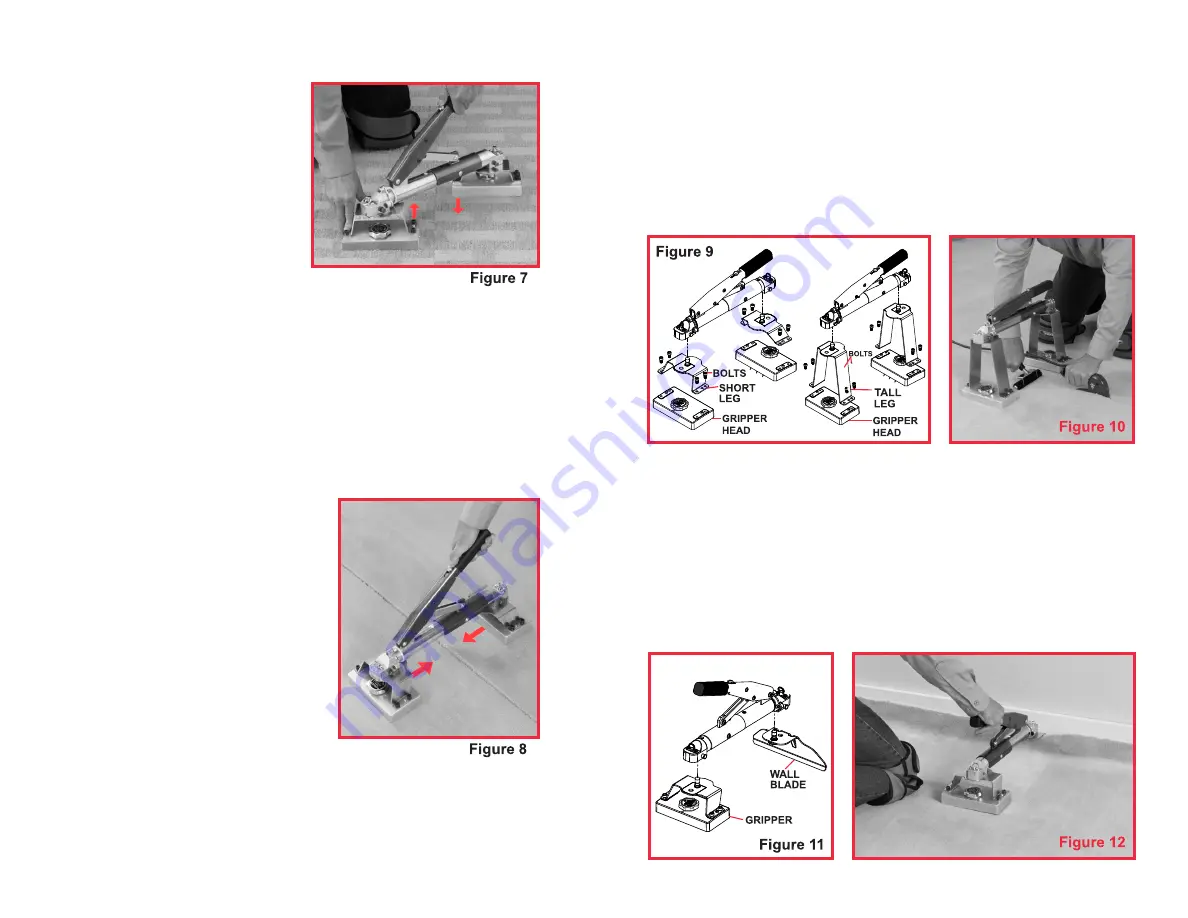

Diagonal stretching (Figure 7)

across the seam can help with

smaller adjustments, particularly

correcting edge deviation or closing

gaps. The dual pivoting grippers can

be positioned at different angles as

desired to pull the seams together

at the angle that produces the right

adjustment.

PATTERN MATCHING PRO TIPS:

Cuts should be arranged so the longest pattern is installed first. Dry lay

the carpet prior to applying adhesive. Pre-stretch the carpet only enough

to match the pattern fairly closely, but do not attempt final alignment. For

final pattern alignment, apply adhesive to the subfloor with the proper

notched trowel, but apply only to those areas on either side of the seam

being presently aligned, so that alignment can be achieved before

adhesive tacks up. Set the carpet into the wet adhesive, then stretch into

final alignment. The use of stay nails is required to hold the carpet in place

until the adhesive is fully cured.

3

SEAM REPAIR USAGE:

Install both gripper heads on the tool as

shown in Figure 5, and set pin depth so

that the pins extend into, but not through,

the carpet’s backing.

To open a seam for repair, place the

gripper heads on either side of the seam,

with each head oriented parallel to the

seam (Figure 8). For this usage, it can

be helpful to lock the gripper heads

perpendicular to the leverage handle

using the pivot lock pins (Figure 3).

Lower the leverage handle to pull the

seam edges together to open the seam

as needed.

Once the seam is opened, you can cut apart the portion requiring repair

and apply latex or other form of adhesive to perform repairs as necessary.

It is usually advisable to re-seal seam edges to prevent unraveling,

delamination, or loss of tufts. Allow adhesive to fully cure before removing

the tool. Otherwise, it is necessary to use stay nails.

SEAM REPAIR WITH A SEAMING IRON:

Tall seam repair legs are available as an accessory (Crain No. 519) to

allow a carpet seaming iron to pass underneath the tool more conveniently

(Figure 10). To install the tall seam repair legs on both ends, depress the

quick-change push button on either end, and remove both gripper head

and short leg assemblies (Figure 9). Using the provided hex wrench,

unscrew the four bolts, and remove the short legs from the gripper heads.

Attach the tall seam repair legs to each of the gripper heads using the

same four bolts. Depress the quick-change push button on either end to

reinsert the tall leg pins in the sockets, and release push button to lock.

STRETCHING CARPET:

The Mini-Stretcher is convenient for removing undesired humps that may

be present in improperly installed carpet.

NOTE: installing an extra row of strip in front of the existing row is normally

required for reinforcement of the tack strip.

As shown in Figure 11, install the wall blade on the front end of the tool

(nearest the leverage handle). Insert the wall blade behind the carpet and

the tack strip (Figure 12). Lower the leverage handle to stretch the carpet.

4

SHORT LEGS

DISASSEMBLY

TALL LEGS

ASSEMBLY

SEAM IRON GOES UNDER

WITH TALL LEGS

STRETCHING ASSEMBLY

STRETCHING CARPET