15

Compactor Operation, cont.

b) Restoring the compactor to service. When the servicing or maintenance is completed and the compactor is ready to re-

turn to normal operating condition, the following steps shall be taken:

1. Check the machine or equipment and the immediate area around the machine or equipment to ensure that all non-

essential items have been removed and the machine or equipment components are operationally intact.

2. Check the work area to insure that all employees have been safely positioned or removed from the area.

3. Verify that the controls are in neutral.

4. Remove the lockout devices and re-energize the machine of equipment.

NOTE: The removal of some forms of blocking may require re-energizing of the machine before safe removal.

5. Notify affected employees that the servicing or maintenance is completed and the machine or equipment is ready for

use.

5. Procedures for work in confined spaces:

a) The owner/employer shall have a written procedure for work in confined spaces meeting the criteria of “permit required

confined spaces," such as integrated power units. The procedure shall utilize the manufacturer’s instructions for the haz-

ardous energy control (lockout/ tag-out) procedure which shall isolate and render safe energy sources, including electri-

cal, mechanical, hydraulic, pneumatic, chemical, thermal or other potential sources of energy (e.g., gravity, kinetic, etc.),

which may create a hazard during entry into each of those confined spaces

b) These instructions shall include the requirement to affix a sign to the compactor, at or near the entrances to those con-

fined spaces for which hazardous energy control procedures are provided, such s, “

Warning — Follow lockout/tag-out

procedures

.”

c) These instructions shall include the requirement to affix a sign to the stationary compactor, at or near the entrances to

those confined spaces for which hazardous energy control procedures are provided, such as, “

Danger — Confined

Space

.”

Safety and training program

General:

Employers shall evaluate and manage safety issues related the operation of compaction equipment as part of

their safety program

Safety Program

The employer’s program shall include at a minimum the following elements:

a) A hazard assessment in which the employer conducts a review of the various types of compaction equipment that

the employer utilizes and the hazards associated with them and, review and assess the capabilities, qualifications

and training of any person who may potentially encounter these hazards.

b) An evaluation of the means and methods of controlling the hazards identified in the hazard assessment, including

information such as industry and regulatory requirements, instructions for the operation, inspection, and mainte-

nance of compactors, and other information appropriate to the hazards that are identified.

c) A written program, based upon the hazard assessment and evaluation, to include procedure for the operation, in-

spection, and maintenance of compactors, prohibited practices, record keeping, training requirements, and norma-

tive references to documents, such as operating manuals, that are relied upon and may be required as part of that

program.

d) Periodic review and program revisions as necessary to ensure the effectiveness of the safety program.

General training

Employers shall ensure all employees, including supervisors, contract laborers, and all other persons engaged in the opera-

tion, cleaning, maintenance, service or repair of compacting equipment are properly trained appropriate for their assigned

jobs and tasks. Contractors who may be engaged to operate or maintain the employer’s compactor shall be advised of the

unique hazards related to the equipment that may affect the activities in which the contractor’s employees will engage.

Summary of Contents for SCR-02

Page 2: ...2 ...

Page 4: ...4 ...

Page 8: ...8 ...

Page 9: ...9 Operation Section ...

Page 10: ...10 SAFETY DECALS ...

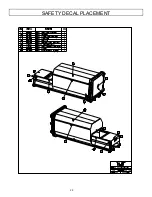

Page 11: ...11 SAFETY DECAL PLACEMENT ...

Page 19: ...19 Authorized Technician Maintenance Section ...

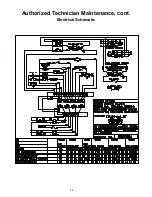

Page 24: ...24 Authorized Technician Maintenance cont Electrical Schematic ...

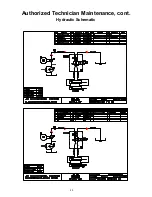

Page 25: ...25 Authorized Technician Maintenance cont Hydraulic Schematic ...

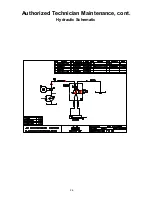

Page 26: ...26 Authorized Technician Maintenance cont Hydraulic Schematic ...

Page 28: ...28 Parts Section ...

Page 29: ...29 SAFETY DECAL PLACEMENT ...

Page 30: ...30 Installation Section ...

Page 33: ...33 Hauler Section ...