22

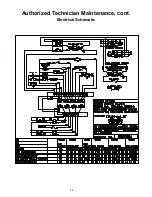

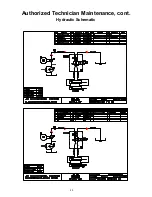

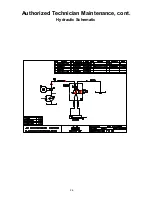

Authorized Technician Maintenance, cont.

4. YEARLY

CHECK:

a. Electrician to check all electrical connections, check motor resistance (recording successive readings helps pre-

vent future failure), Under heavy use, grease the motor. (DO NOT OVER-GREASE).

b. Hydraulic system—prior to winter season, drain, replace filter, and clean inside of reservoir by removing drain

plug. Replace plug and refill. Check for tightness. Refill reservoir with high quality 5W-20 Hydraulic fluid.

c.

Check structure for potential trouble areas and repair as needed.

d. Check hoses to insure that they do not become severely worn before being replaced. A broken hose will allow

the reservoir to be pumped dry and ruin the pump.

e. Check condition of ram guide shoes. Replace if necessary.

Keeping the slide material replaced when neces-

sary will greatly extend the life of the compactor floor and sides

.

*

*

LUBRICATION:

NOTE: Clean-out or maintenance requires the loading chamber cover be open, but be sure the compactor ram is

extended first. To EXTEND the ram - - first turn the “start” switch and fully extend the ram. When ram is fully ex-

tended , press the “STOP” button, and remove the key,

lockout/tag-out

the power, then the cover can be removed.

Warning: Before removing any access panels or entering charge chamber, make absolutely sure

main disconnect power box is shut off and locked, with key to said lock in possession of

person entering charge chamber or area behind bolted access covers. A tag should also be

attached to the disconnect stating “UNDER REPAIR, DO NOT USE”, with persons name on

the tag who is entering behind the ram.

*

Open the access cover on the top of the compactor by removing the attached bolts. When lubrication or maintenance is

complete, replace the cover before any operation.

Warning: This procedure is for maintenance only. All access covers shall be replaced and bolted into

position after lubrication or clean-out.

We recommend the user of

CRAM-A-LOT

®

compactors adopt a program of regularly scheduled maintenance procedures. This

schedule should be followed to insure against premature failure of mechanical or hydraulic components.

1. INITIAL

CHECK:

a. All nuts and bolts during the first week of use, and then monthly thereafter.

b. Hydraulic reservoir should be at the mid to upper range of the sight glass with ram retracted. Use a good quality

5W-20 Hydraulic fluid.

c.

Hydraulic lines for leaks.

d. Hydraulic hose condition. (Check for damage, kinks, etc.).

e. Access covers to be sure fasteners are in place.

f.

Power unit. Remove dust and dirt from outside of control box. Wipe off any dirt or grease, oil or moisture.

2. MONTHLY

CHECK:

a. Check external hoses for chafing, rubbing, or other deterioration and damage.

b. Check for any obvious unsafe conditions, such as electrical lines or operator obstructions, in compactor area.

c.

Check oil level in hydraulic reservoir.

d. Check functional operation of standard controls and options (stop button, timers, lights, etc.).

e. Check hydraulic cylinder and internal hoses for leakages, hoses for chafing and wear.

PREVENTIVE MAINTENANCE

Summary of Contents for SCR-02

Page 2: ...2 ...

Page 4: ...4 ...

Page 8: ...8 ...

Page 9: ...9 Operation Section ...

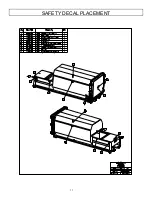

Page 10: ...10 SAFETY DECALS ...

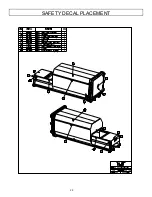

Page 11: ...11 SAFETY DECAL PLACEMENT ...

Page 19: ...19 Authorized Technician Maintenance Section ...

Page 24: ...24 Authorized Technician Maintenance cont Electrical Schematic ...

Page 25: ...25 Authorized Technician Maintenance cont Hydraulic Schematic ...

Page 26: ...26 Authorized Technician Maintenance cont Hydraulic Schematic ...

Page 28: ...28 Parts Section ...

Page 29: ...29 SAFETY DECAL PLACEMENT ...

Page 30: ...30 Installation Section ...

Page 33: ...33 Hauler Section ...