English

Sweeper

Original Operation Manual

-11

6

Maintenance

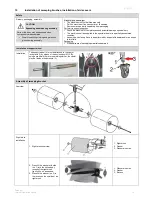

6.1 Safety during maintenance work

Regular and correctly performed maintenance work is essential for the

safe, economical and fault-free operation of the machine.

The information in the following sections help you to ensure the

correct maintenance of your machine. You can perform routine

maintenance work yourself using basic hand tools. More complex

maintenance work requiring special tools should be performed by

qualified staff, e.g. at your Cramer dealer or by a qualified mechanic.

Some of the most important safety precautions and dangers are listed

in the box below. However, it is not possible here to list all potential

dangers that could arise during maintenance work and describe the

associated precautions. You are solely responsible for deciding which

maintenance work you wish to perform yourself.

DANGER!

Risk of injury by inappropriately performed

maintenance work!

Defective work may result in serious bodily injuries and damage to

property.

Make sure that you have sufficient working space.

Remove the battery from the compartment.

Place components separately.

Remount all components.

Remount all safety covers.

Keep the risk area clear of persons.

6.2 Maintenance plan

For information on maintenance of the motor, refer to the

separate operation manual of the motor.

Maintenance

Prior to

each use

Annually

Intervals

in hours

200

Cleaning

X

(Item 6.4)

Check safety precautions

X

(Item

6.3.1)

Check all screws for tight

fitting

O

Clean or replace air filter

B

Adjust tyre pressure

O

Check sweeping brushes

for tapes wrapped

around

O

Check sweeping brush

height adjustment

X

(Item 3.3)

Check sweeping brush

for wear

O

Check and adjust

Bowden cables

F

Grease rotating points

and joints

O

Grease Bowden cables

O

Check machine for

corrosion on paint

coating and remedy as

appropriate

O

Check machine for

damage and remedy as

appropriate

O

X = Described in this Operation Manual in the indicated

section

O = Not described in the present Operation Manual

F = Work may only be performed by a

qualified expert in this field.

B = Description is enclosed in attached motor operation instructions.

6.3 Maintenance work

Only original parts should be used for maintenance. Spare parts

should be replaced by an authorized service engineer.

CAUTION !

Risk of injuries from motor and battery

Cleaning and repair work must never be performed when the

battery is inserted, since an unintentional start of the machine

could result in serious injuries.

Remove the battery and let the machine cool down.

WARNING!

Never open the battery! Risk of explosion and

injuries!

The batteries are absolutely maintenance-free. Do never attempt to

open them.

Replace damaged batteries by new ones. . Old, defective

batteries must not be disposed of in domestic waste.

6.3.1 Check safeguards

Safeguards are:

- Rubber side guard for stone chip protection

- Motor cover (splashguard as all-weather accessory package)

- Cover plate

The machine must not be operated if the covers show any signs of

damage or are removed. They are to be replaced by original spare

parts in case of damage or loss. The machine must not be started

without the safeguards.

6.4 Maintenance work on electric motor

Repair and maintenance work on the motor required special protection

and knowledge. Such work should only be performed by qualified

staff.

6.5 Cleaning work

WARNING !

For the prevention of fire or electric shock:

1. Do not use damp cloths or cleanser for cleaning the battery, the

battery compartment or the charger.

2. Always remove the battery when working on the machine.

The machine should be cleaned regularly so that any damage to the

paint coating or plastic components can be detected. Please observe

the notes listed for cleaning in order to avoid damage to the

electronics.

6.5.1 Machine cleaning

Park the machine on an even surface before cleaning it. Switch off the

machine and allow the motor to cool down. The machine can then be

cleaned using a soft brush. If necessary, subsequently wipe the

machine (except for battery or battery compartment) with a damp

cloth.

Attention! The battery system must not be exposed to humidity.