12

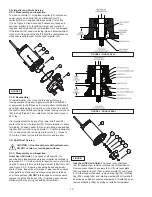

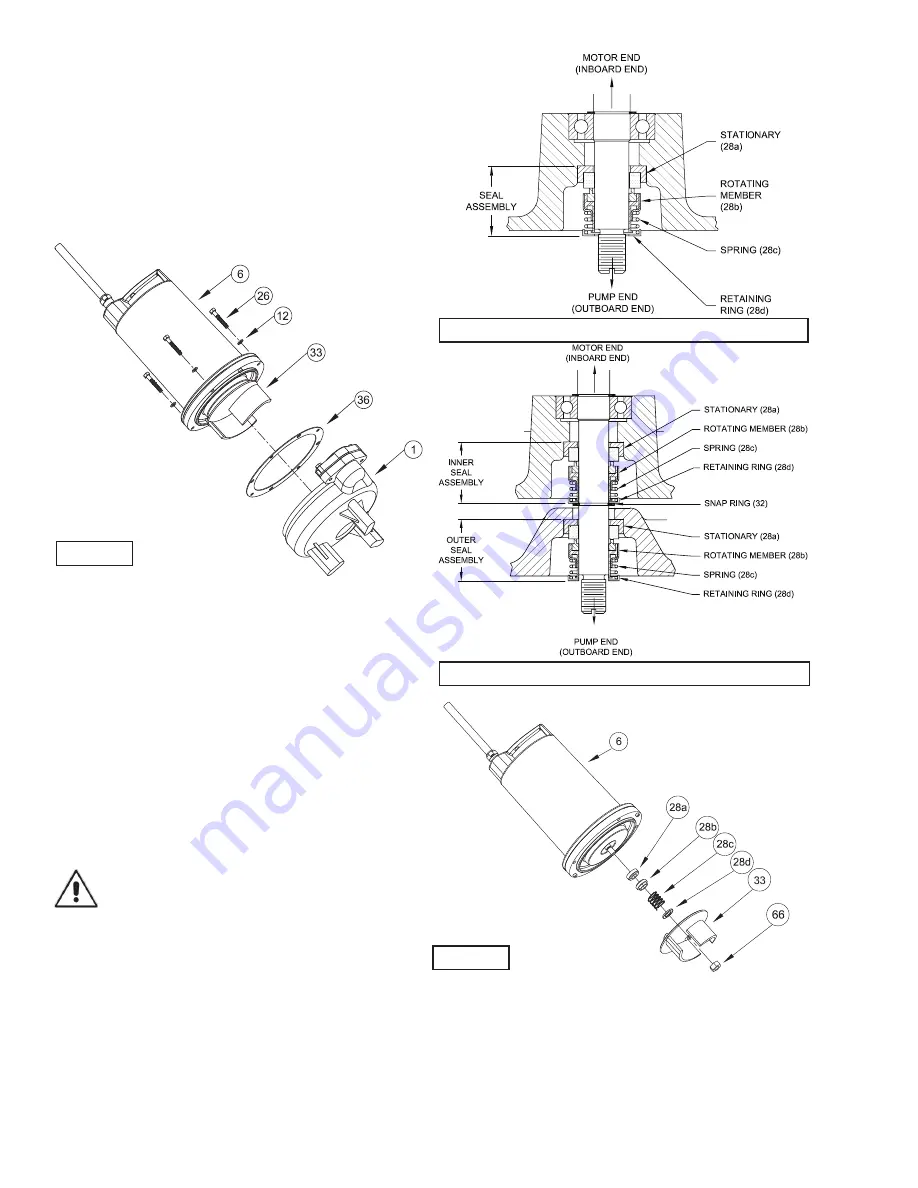

F-2) Impeller and Volute Service:

F-2.1) Disassembly and Inspection:

To clean out volute (1) or replace impeller (33), disconnect

power, remove hex bolts (26), and lockwashers (12),

vertically lift motor and seal plate assembly from volute

(1) see Figure 5. Clean out body if necessary. Clean and

examine impeller (33), for pitting or wear and replace if

required, inspect gasket (36) and replace if cut or damaged.

If the impeller (33) needs replacing, place a flat screwdriver

in the slot of the end of the shaft to hold the shaft stationary

while unscrewing the jam nut (66) and impeller (33).

F-2.2) Reassembly:

To install impeller (33), clean the threads with thread

locking compound cleaner. Apply removable Loctite® 603

or equivalent to shaft threads. Screw impeller onto the shaft

hand tight while using a screwdriver in the slot at the end of

the shaft to hold it stationary. Apply thread locking compound

(60) to shaft threads. Then install jam nut (66) and torque to

40 ft. lbs.

It is important that the spring of the lower shaft seal (28)

seats in the hub of the impeller (33). Rotate impeller to check

for binding. Position gasket (36) on volute flange and position

impeller and motor housing on volute (1). Position lockwasher

(12) on cap screw (26) and screw into volute (1). Torque to

100 in-lbs. Check for free rotation of motor and impeller.

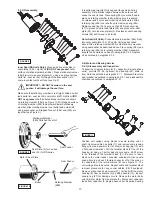

F-3) Shaft Seal Service:

CAUTION ! - Handle seal parts with extreme care.

DO NOT scratch or mar lapped surfaces.

F-3.1) Disassembly and Inspection:

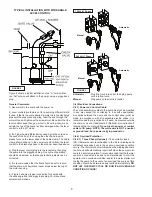

Outer Seal (All Units) -

To expose shaft seal (28) for

examination, disassemble volute and impeller as outlined in

paragraph F-2.1. If further repair is required, remove retaining

ring (28d), spring (28c) and rotating member (28b) from shaft

(see Figure 6 & 7). Examine all seal parts and especially

contact faces. Inspect seal for signs of wear such as uneven

wear pattern on stationary members, chips and scratches

on either seal face.

DO NOT

interchange seal components,

replace the entire shaft seal (28). If replacing seal, remove

stationary (28a) by prying out with flat screwdriver.

Inner Seal (DS Units Only)-

To expose inner shaft seal

(28) for examination, remove outer seal as outlined above.

Remove socket head cap screws (64). Lift outer seal plate

(29) and square-ring (27) from inner seal plate (5) see Figure

8. If further repair is required, remove snap ring (32), retaining

ring (28d), spring (28c) and rotating member (28b) from shaft.

Examine as outlined in outer seal paragraph. If replacing seal,

remove stationary (28a) by prying out with flat screwdriver.

FIGURE 5

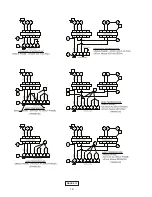

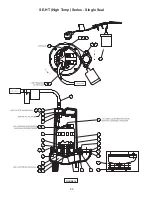

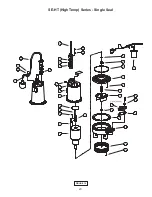

FIGURE 6 - DOUBLE SEAL

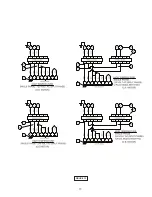

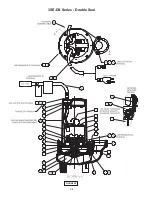

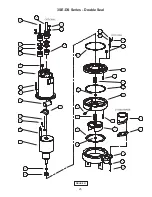

FIGURE 6 - SINGLE SEAL

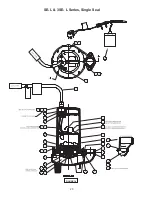

FIGURE 7

Summary of Contents for 104872

Page 16: ...16 FIGURE 13 ...

Page 17: ...17 FIGURE 13 ...

Page 18: ...18 FIGURE 13 CONTIUED ...

Page 20: ...20 FIGURE 16 SE L 3SE L Series Single Seal ...

Page 21: ...21 FIGURE 17 SE L 3SE L Series Single Seal ...

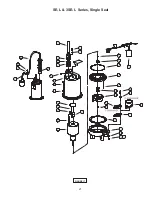

Page 22: ...22 FIGURE 18 SE HT High Temp Series Single Seal ...

Page 23: ...23 FIGURE 19 SE HT High Temp Series Single Seal ...

Page 24: ...24 FIGURE 20 3SE DS Series Double Seal ...

Page 25: ...25 FIGURE 21 3SE DS Series Double Seal ...

Page 29: ...29 Notes ...

Page 30: ...30 Notes ...