13

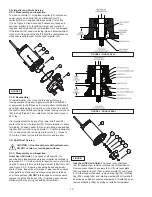

F-3.2) Reassembly:

Inner Seal (DS Units Only)-

Clean and oil seal cavities in

seal plates (5, 29). Lightly oil

(DO NOT use grease)

outer

surface of stationary member (28a). Press stationary member

(28a) firmly into inner seal plate (5), using a seal pusher (see

parts list - seal tool kit). Nothing but the seal pusher is to

come in contact with seal face (see Fig 9).

IMPORTANT! - DO NOT hammer on the seal

pusher- it will damage the seal face.

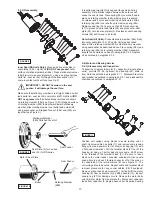

Make sure the stationary member is in straight. Slide a bullet

(see parts list - seal tool kit) over motor shaft. Lightly oil

(DO

NOT use grease)

shaft, bullet and inner surface of bellows

on rotating member (28b) see Figure 10. With lapped surface

of rotating member (28b) facing inward toward stationary

member, slide rotating member over bullet and onto shaft,

using seal pusher, until lapped faces of (28a) and (28b) are

together (see Figure 9).

It is extremely important to keep seal faces clean during

assembly. Dirt particles lodged between these faces will

cause the seal to leak. Place spring (28c) over shaft and in

place on rotating member (28b), making sure it is seated

on retainer and not cocked or resting on bellows tail. Slide

retaining ring (28d) over shaft and let rest on spring (28c).

Replace snap ring (32) in groove of shaft. Set square-ring

(27) in groove on outer seal plate (29) and place outer seal

plate (29) onto inner seal plate (5). Replace socket head cap

screws (64) and torque to 60 in-lbs.

Outer Seal (All Units)-

Press stationary member (28a) firmly

into outer seal plate (5, or 29 on DS Units) as described

above. Slide rotating member (28b) onto stationary member

using seal pusher as described above. Place spring (28c) and

retaining ring (28d) onto rotating member (28b). Assemble

impeller and volute as outlined in paragraph F-2.2. Replace

oil as outlined in paragraph F-1.4.

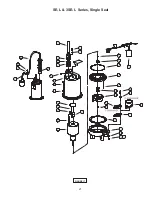

F-4) Motor and Bearing Service

F-4.1) Disassembly and Inspection:

To examine or replace the motor (7), capacitor (9, single phase

units), controls (55, 56, optional), and bearing (25), drain oil

from motor as outlined in paragraph F-1.1. Disassemble volute

and impeller as outlined in paragraph F-2.1 and disassemble

shaft seal as outlined in paragraph F-3.1.

Position unit upright, using blocks to avoid resting unit on

shaft. Unscrew cable hex bolts (11) and remove compression

flange (16a) and power cord (16). Remove snap ring (19) with

a flat head screwdriver. Pull the terminal block (21) out of the

housing (6) using a T-bolt or pair of pliers and a .25-20 screw

in the threads of the terminal block (21). Be sure to leave

slack on the motor leads connected underneath. Use needle

nose pliers to pull each female connector off of the pins on

the underside of the terminal block (21) see Figure 11. The

unit voltage should be noted. Repeat cable and terminal block

removal procedure for any control cables (56) if equipped.

Remove socket head cap screws (47). Vertically lift the motor

housing (6) from seal plate (5) by lifting handle (13). Inspect

square ring (27) for damage or cuts. Remove the motor bolts

and lift motor stator from seal plate (5). Disconnect capacitor

leads from capacitor (9, single phase units). Examine bearing

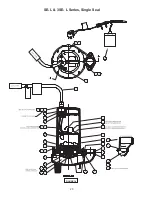

Stationary Member

(28A) Polished Face Out

Seal Pusher

Seal Plate (5) for L series

and (29) for DS series

FIGURE 9

Motor & Seal Plate

Bullet

Rotating Member

(28B)

Seal Pusher

FIGURE 10

FIGURE 8

FIGURE 11

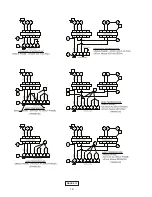

Summary of Contents for 104872

Page 16: ...16 FIGURE 13 ...

Page 17: ...17 FIGURE 13 ...

Page 18: ...18 FIGURE 13 CONTIUED ...

Page 20: ...20 FIGURE 16 SE L 3SE L Series Single Seal ...

Page 21: ...21 FIGURE 17 SE L 3SE L Series Single Seal ...

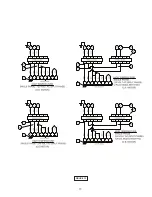

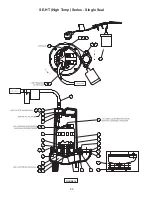

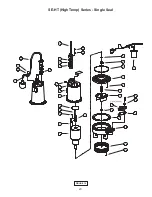

Page 22: ...22 FIGURE 18 SE HT High Temp Series Single Seal ...

Page 23: ...23 FIGURE 19 SE HT High Temp Series Single Seal ...

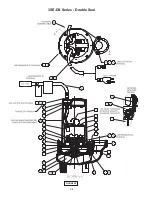

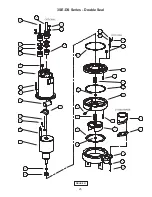

Page 24: ...24 FIGURE 20 3SE DS Series Double Seal ...

Page 25: ...25 FIGURE 21 3SE DS Series Double Seal ...

Page 29: ...29 Notes ...

Page 30: ...30 Notes ...