Snack / Refreshment Center Setup and Operator's Guide

Page 33

1670001

April, 1999

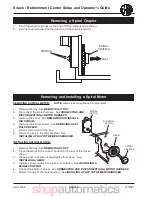

Adjusting the price roll:

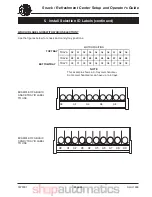

You can set selection prices within the following range:

Minimum price

$

.00

Maximum price $ 12.95

Increment

$

.05

1.

Use your thumb as shown to move each price roll up or down as needed to set the desired price.

NOTE

You will see the word STOP near either end of the roll.

SB&&9,.-177&1,8&L$-&!%*2$&K1T$7.&:2",-*,)$8;

Summary of Contents for 787E

Page 2: ......