21

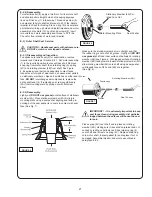

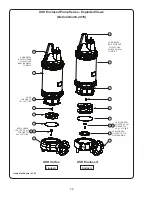

E-2.2) Reassembly:

To install impeller (6), apply a thin film of oil to motor shaft

and slide impeller straight onto shaft, keeping keyways

lined up. Drive key (7) into keyway. Thread cap screw (8)

and washer (8A) into shaft and torque to 45 ft. lbs. Rotate

impeller to check for binding. Place o-ring (9) on seal plate

pilot diameter lining up holes and install impeller and motor

assembly onto volute (10). Loctite cap screws (2), insert

into volute and motor assembly and torque to 35 ft. lbs.

Check for free rotation of motor and impeller.

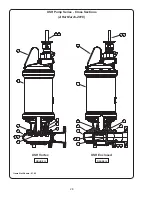

E-3) Outer Shaft Seal Service:

CAUTION ! - Handle seal parts with extreme care.

DO NOT scratch or mar lapped surfaces.

E-3.1) Disassembly and Inspection:

To expose outer shaft seal (4) for examination, remove

Impeller and Volute per Section E-2.1. Set motor assembly

(1) in the inverted position to prevent loss of oil. Remove

snap ring from motor shaft, then retaining ring (5), spring

(4C) and rotating member (4B) from shaft, See Figure

6. Examine all seal parts and especially contact faces.

Inspect seal for signs of wear such as uneven wear pattern

on stationary members, chips and scratches on either seal

face.

DO NOT

interchange seal components, replace the

entire shaft seal (4). If replacing seal, remove stationary

(4A) from mounting plate by prying out with flat screw

driver.

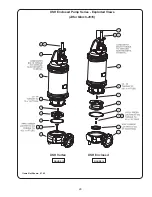

E-3.2) Reassembly:

Lightly oil

(DO NOT use grease)

outer surface of stationary

member (4A). Press stationary member (4A) firmly into

mounting plate using a seal pusher aligning seal with pin,

nothing but the seal pusher is to come in contact with seal

face (See Fig. 7).

Make sure the stationary member is in straight and that

the rubber ring is not out of it’s groove. Lightly oil

(DO NOT

use grease)

shaft and inner surface of bellows on rotating

member (4B) see Figure 8. With lapped surface of rotating

member (4B) facing inward toward stationary member (4A),

slide rotating member (4B) onto shaft using a seal pusher,

until lapped faces of (4A) and (4B) are together.

(See Fig. 8).

IMPORTANT ! - It is extremely important to keep

seal faces clean during assembly. dirt particles

lodged between these faces will cause the seal

to leak.

Place spring (4C) over shaft and in place on rotating

member (4B), making sure it is seated on retainer and not

cocked or resting on bellows tail. Slide retaining ring (5)

over shaft and let rest on spring (4C). Replace snap ring

onto motor shaft. Inspect gasket (9) and replace if cut or

damaged. Assemble impeller and volute as outlined in

paragraph E-2.2.

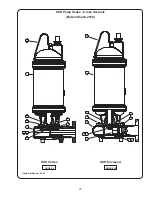

FIGURE 6

Stationary Member (4A) Pol-

ished Face Out

Motor Mounting Plate

Seal Pusher

FIGURE 7

Rotating Member (4B)

Bullet

Motor

Seal Pusher

Stationary

FIGURE 5

Summary of Contents for BARNES 10XSHD

Page 48: ...Notes ...