24

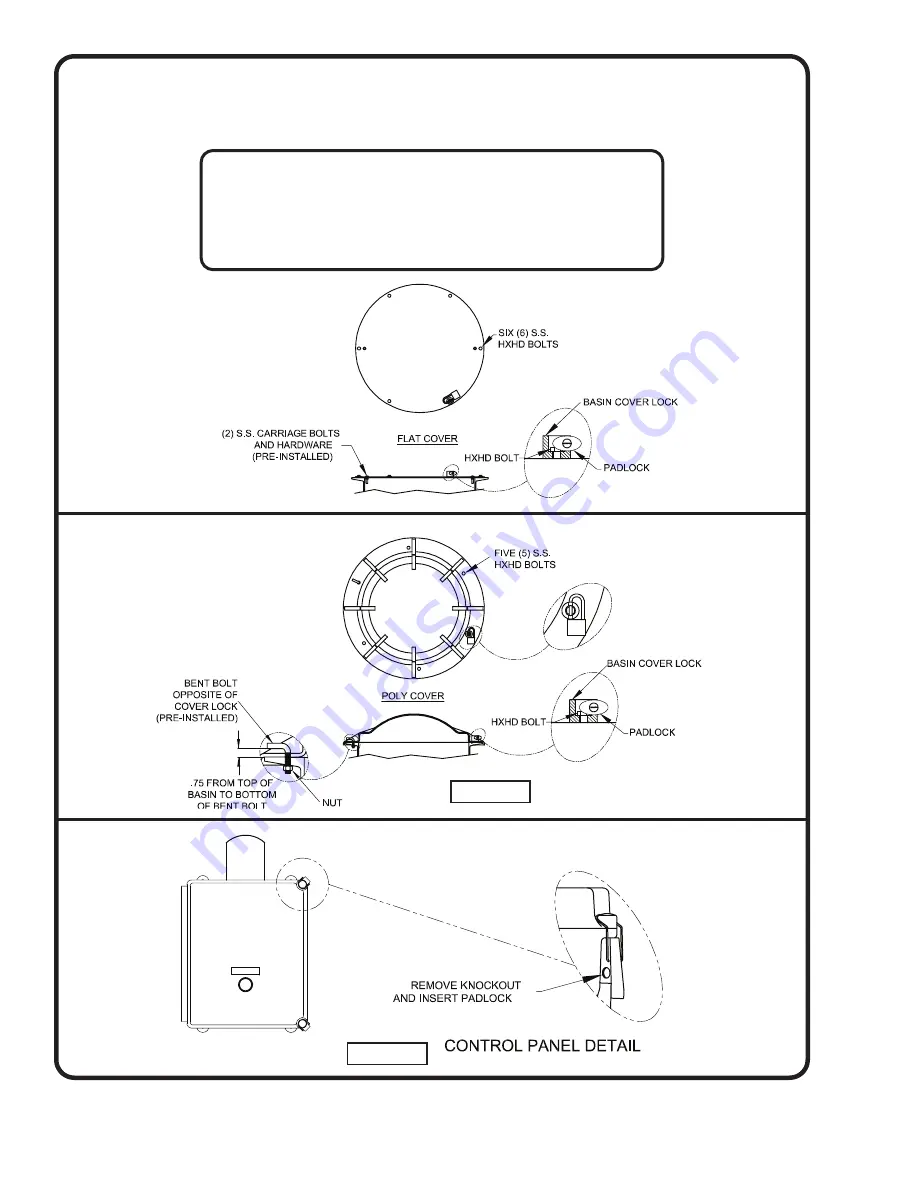

Optional -

Installation of

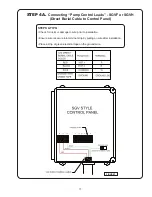

Basin Cover & Control Panel Locks

STEPS & TIPS:

• Use the Illustration that represents your cover style.

• Install the lock as shown in Figure 23.

• The basin cover lock requires a 9/16” socket to tighten or loosen bolt.

• Remove the knockouts on control panel and insert lock.

FIGURE 23

FIGURE 24