A Crane Co. Company

420 Third Street

83 West Drive, Brampton

Piqua, Ohio 45356

Ontario, Canada L6T 2J6

Phone: (937) 778-8947

Phone: (905) 457-6223

Fax: (937) 773-7157

Fax: (905) 457-2650

www.cranepumps.com

Limited 24 Month Warranty

Crane Pumps & Systems warrants that products of our manufacture will be free of defects in material and workmanship

under normal use and service for twenty-four (24) months after manufacture date, when installed and maintained

in accordance with our instructions.This warranty gives you specifi c legal rights, and there may also be other rights

which vary from state to state. In the event the product is covered by the Federal Consumer Product Warranties Law

(1) the duration of any implied warranties associated with the product by virtue of said law is limited to the same

duration as stated herein, (2) this warranty is a LIMITED WARRANTY, and (3) no claims of any nature whatsoever

shall be made against us, until the ultimate consumer, his successor, or assigns, notifi es us in writing of the defect,

and delivers the product and/or defective part(s) freight prepaid to our factory or nearest authorized service station.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply.

THE SOLE AND EXCLUSIVE REMEDY FOR BREACH OF ANY AND ALL WARRANTIES WITH RESPECT TO ANY

PRODUCT SHALL BE TO REPLACE OR REPAIR AT OUR ELECTION, F.O.B. POINT OF MANUFACTURE OR

AUTHORIZED REPAIR STATION, SUCH PRODUCTS AND/OR PARTS AS PROVEN DEFECTIVE. THERE SHALL BE

NO FURTHER LIABILITY, WHETHER BASED ON WARRANTY, NEGLIGENCE OR OTHERWISE.

Unless expressly

stated otherwise, guarantees in the nature of performance specifi cations furnished in addition to the foregoing material

and workmanship warranties on a product manufactured by us, if any, are subject to laboratory tests corrected for

fi eld performance. Any additional guarantees, in the nature of performance specifi cations must be in writing and such

writing must be signed by our authorized representative. Due to inaccuracies in fi eld testing if a confl ict arises between

the results of fi eld testing conducted by or for user, and laboratory tests corrected for fi eld performance, the latter

shall control.

RECOMMENDATIONS FOR SPECIAL APPLICATIONS OR THOSE RESULTING FROM SYSTEMS

ANALYSES AND EVALUATIONS WE CONDUCT WILL BE BASED ON OUR BEST AVAILABLE EXPERIENCE AND

PUBLISHED INDUSTRY INFORMATION. SUCH RECOMMENDATIONS DO NOT CONSTITUTE A WARRANTY OF

SATISFACTORY PERFORMANCE AND NO SUCH WARRANTY IS GIVEN.

This warranty shall not apply when damage is caused by (a) improper installation, (b) improper voltage (c) lightning

(d) excessive sand or other abrasive material (e) scale or corrosion build-up due to excessive chemical content. Any

modifi cation of the original equipment will also void the warranty. We will not be responsible for loss, damage or labor

cost due to interruption of service caused by defective parts. Neither will we accept charges incurred by others without

our prior written approval.

This warranty is void if our inspection reveals the product was used in a manner inconsistent with normal industry practice

and\or our specifi c recommendations. The purchaser is responsible for communication of all necessary information

regarding the application and use of the product.

UNDER NO CIRCUMSTANCES WILL WE BE RESPONSIBLE FOR

ANY OTHER DIRECT OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO TRAVEL EXPENSES,

RENTED EQUIPMENT, OUTSIDE CONTRACTOR FEES, UNAUTHORIZED REPAIR SHOP EXPENSES, LOST

PROFITS, LOST INCOME, LABOR CHARGES, DELAYS IN PRODUCTION, IDLE PRODUCTION, WHICH DAMAGES

ARE CAUSED BY ANY DEFECTS IN MATERIAL AND\OR WORKMANSHIP AND\OR DAMAGE OR DELAYS IN

SHIPMENT. THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER EXPRESS OR IMPLIED WARRANTY,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

.

No rights extended under this warranty shall be assigned to any other person, whether by operation of law or otherwise,

without our prior written approval.

Summary of Contents for Barnes PS Omni Grind Plus OGP2022CO Series

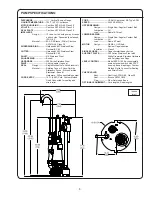

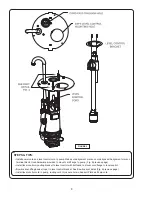

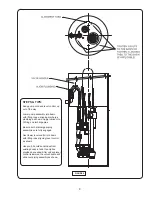

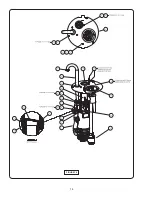

Page 11: ...11 FIGURE 8 ...

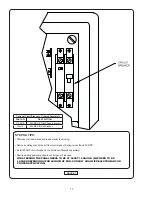

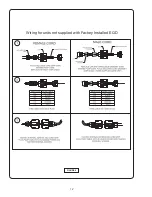

Page 12: ...12 FIGURE 9 Wiring for units not supplied with Factory Installed EQD ...

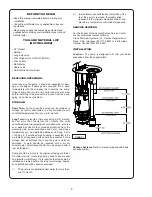

Page 13: ...13 Wiring for Optional Remote Alarm Light ...

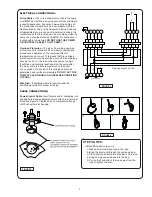

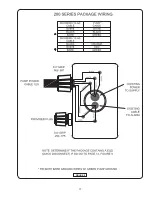

Page 14: ...14 FIGURE 10 ...

Page 16: ...Notes ...