3

Please Read This Before Installing Or Operating Pump.

This information is provided for

SAFETY and to PREVENT

EQUIPMENT PROBLEMS

. To help recognize this information,

observe the following symbols:

IMPORTANT!

Warns about hazards that can result

in personal injury orIndicates factors concerned with

assembly, installation, operation, or maintenance which

could result in damage to the machine or equipment if

ignored.

CAUTION !

Warns about hazards that can or will cause minor

personal injury or property damage if ignored. Used with symbols

below.

WARNING !

Warns about hazards that can or will cause serious

personal injury, death, or major property damage if ignored. Used

with symbols below.

Only qualifi ed personnel should install, operate and repair pump.

Any wiring of pumps should be performed by a qualifi ed electrician.

WARNING! -

To reduce risk of electrical shock, pumps and

control panels must be properly grounded in accordance

with the National Electric Code (NEC) or the Canadian

Electrical Code (CEC) and all applicable state, province,

local codes and ordinances.

WARNING! -

To reduce risk of electrical shock, always

disconnect the pump from the power source before

handling or servicing. Lock out power and tag.

Prevent large articles of clothing, large amounts of chemicals, other

materials or substances such as are uncommon in domestic sewage

from entering the system.

Minimize the amount of cooking grease entering the system.

DO NOT

leave pump cover off the basin, except while servicing,

to prevent entrance of foreign materials such as rocks, metal, soil,

animals or humans.

Prevent infi ltration or direct fl ow of rain or run-off water into the pump

basin to minimize pump cycling. This will prevent overloading the

treatment facility, and will facilitate swift transportation of sewage.

During power black-outs, minimize water consumption at the

home(s) to prevent sewage from backing up into the house.

Keep the control panel locked or confi ned to prevent unauthorized

access to it.

If the pump is idle for long periods of time, it is advisable to start the

pump occasionally by adding water to the basin.

Always keep the shut-off valve completely open when system is

in operation (unless advised otherwise by the proper authorities).

Before removing the pump from the basin, be sure to close the shut-

off valve. (This prevents backfl ow from the pressure sewer.)

CAUTION!

Pumps build up heat and pressure

during operation-allow time for pumps to cool

before handling or servicing.

WARNING!

-

DO NOT

pump hazardous materials

(fl ammable, caustic, etc.) unless the pump is specifi cally

designed and designated to handle them.

WARNING! - DO NOT

wear loose clothing that may

become entangled in the impeller or other moving parts.

WARNING! -

Keep clear of suction and discharge

openings.

DO NOT

insert fi ngers in pump with power

connected.

Always wear appropriate safety gear, such as safety

glasses, when working on pump or piping.

Make sure lifting handles are securely fastened each time before

lifting. Do not operate pump without safety devices in place. Always

replace safety devices that have been removed during service or

repair.

Do not exceed manufacturers recommendation for maximum

performance, as this could cause the motor to overheat.

Cable should be protected at all times to avoid punctures,

cut, bruises and abrasions - inspect frequently.

Never handle connected power cords with wet hands.

To reduce risk of electrical shock, all wiring and junction

connections should be made per the NEC or CEC and

applicable state or province and local codes. Requirements

may vary depending on usage and location.

Do not remove cord and strain relief. Do not connect

conduit to pump.

Products Returned Must Be Cleaned, Sanitized, Or

Decontaminated As Necessary Prior To Shipment, To

Insure That Employees Will Not Be Exposed To Health

Hazards In Handling Said Material. All Applicable Laws

And Regulations Shall Apply.

Bronze/brass and bronze/brass fi tted pumps may contain

lead levels higher than considered safe for potable

water systems. Lead is known to cause cancer and birth

defects or other reproductive harm. Various government

agencies have determined that leaded copper alloys

should not be used in potable water applications. For

non-leaded copper alloy materials of construction, please

contact factory.

IMPORTANT! -

Crane Pumps & Systems, Inc. is not

responsible for losses, injury, or death resulting from a

failure to observe these safety precautions, misuse or

abuse of pumps or equipment.

SAFETY FIRST!

Hazardous fl uids can

cause fi re or explo-

sions, burnes or death

could result.

Extremely hot - Severe

burnes can occur on contact.

Biohazard can cause

serious personal injury.

Hazardous fl uids can Hazard-

ous pressure, eruptions or ex-

plosions could cause personal

injury or property damage.

Rotating machinery

Amputation or severe

laceration can result.

Hazardous voltage can shock,

burn or cause death.

Other brand and product names are trademarks or registered trademarks of their respective holders.

® Barnes is a registered trademark of Crane Pumps & Systems Inc.

1/2005,

8/05,

12/05,

1/06,

9/06 Alteration

Rights

Reserved

Summary of Contents for Barnes PS Omni Grind Plus OGP2022CO Series

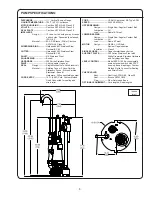

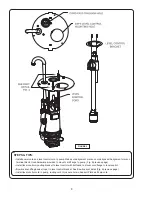

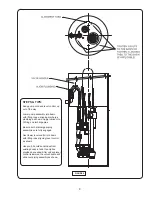

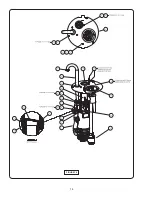

Page 11: ...11 FIGURE 8 ...

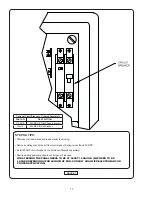

Page 12: ...12 FIGURE 9 Wiring for units not supplied with Factory Installed EQD ...

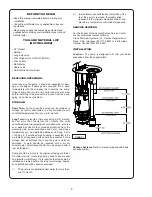

Page 13: ...13 Wiring for Optional Remote Alarm Light ...

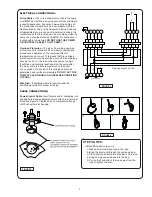

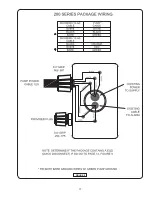

Page 14: ...14 FIGURE 10 ...

Page 16: ...Notes ...