5

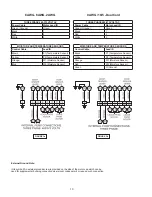

B-3) Liquid Level Controls:

It is recommended to use a liquid level control system

that allows the on and off point to be separated by at least

twelve inches. An additional set point (lag point) should

be incorporated with an alternator switching system for

a duplex (two pump) station. A high level alarm may be

required to alert maintenance personnel that there is a

high water situation in the wet well should the output of the

pump station drop below the inflow rate. A low level cut off

may be installed to provide system shutdown if the main

level control system malfunctions. The off point should be

positioned so that the liquid level never drops below the

minimum continuous duty point for the pump shown in

Figure 1.

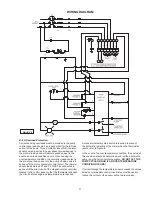

B-4.1) Electrical Connections:

WARNING! - All model pumps and

control panels must be properly

grounded per the NATIONAL

ELECTRIC CODE or CANADIAN

ELECTRIC CODE, State, Province

and local codes. Improper

grounding voids warranty.

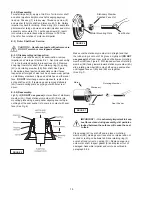

B-4) Power/Control Cord:

The cord assembly mounted to the pump must not be

modified in any way except for shortening to a specific

application. Any splice between the pump and the control

panel must be made in accordance with all applicable

electric codes. It is recommended that a junction box (if

used) be mounted outside the sump or be of at least Nema

6 or 6P construction with NEMA 6 or 6P watertight cord

grips if located within the wet well. A water and vapor tight

seal fitting

MUST

be used in conduit leaving the wet well

to prevent moisture and gases from reaching the control

panel. Prior to installation, the pump power cable should be

inspected for nicks or damage. If damaged, the cord should

be replaced before installation.

Install the cord assembly o-ring onto the cord assembly

as shown in Figure 2. Align the hole in the cord assembly

with the alignment pin in the motor cap. Lower the cord

assembly into the bore of the motor cap taking care to keep

the pins aligned. Push the cord assembly into the motor

housing until fully engaged. Install the four 12mm socket

head cap scews through the cord assembly into the motor

cap. Slowly tighten the four screws alternating in a cross

pattern until the cord assembly is drawn down flush to the

motor cap. The screws should then be torqued to 35 ft. lbs.

CORD CLAMPING PLATE SHOULD BE DRAWN METAL

TO METAL (35 FT/LBS BOLT TORQUE). IF A GAP

EXISTS CONTINUE TO TIGHTEN BOLTS. DO NOT USE

ANY TYPE OF SEALANT OR GREASE ON THE CORD

ENTRY.

DO NOT USE THE POWER CORD TO LIFT PUMP.

NOTE: The White Wire Is Not A Neutral Or Ground

Lead. The Black, White And Red Leads Are Power

Carrying Conductors. The Green Lead Is For

Connection To Ground.

B-4.1) Electrical Connections:

When the electrical connections are made, the lead wires

from the power cable should be stripped so that the ground

wire is at least two inches longer than the power leads.

This will ensure that if the cable is inadvertently pulled out

of the connection point, the ground wire will be the last lead

to break the circuit.

B-4.2) Wire Size:

If additional cable is required consult a qualified electrician

for proper wire size. Voltage drop due to wire resistance

between the pump and power connection point should be

limited to 3% when additional cable is added.

WARRANTY NOTE:

Both the temperature sensor and moisture

detection system must be connected to the

motor circuitry such that the motor will be de-

energized or sound alarm if excessive motor

temperatures are reached and/or if water is

detected in the seal chamber and/or motor

chamber. Failure to have the above mentioned

systems installed and operative, nullifies

warranty

FIGURE 2

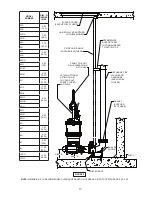

Summary of Contents for DEMING 7365N-X54-95-30N

Page 18: ...18 FIGURE 9 Vortex Enclosed CROSS SECTIONS FIGURE 10 ...

Page 19: ...19 EXPLODED VIEWS FIGURE 11 ...

Page 22: ...22 Notes ...