10

F-3.2) Reassembly:

Bearing

- When replacing bearing, be careful not to damage

the rotor or shaft threads. Clean the shaft thoroughly. Slide

conduit bushing (16) and washers (25), (33) over motor shaft.

Apply adhesive compound to the shaft and press bearing

(21) on the motor shaft, position squarely onto shaft applying

force to the inner race of the bearing only, until bearing seats

against shoulder of the shaft.

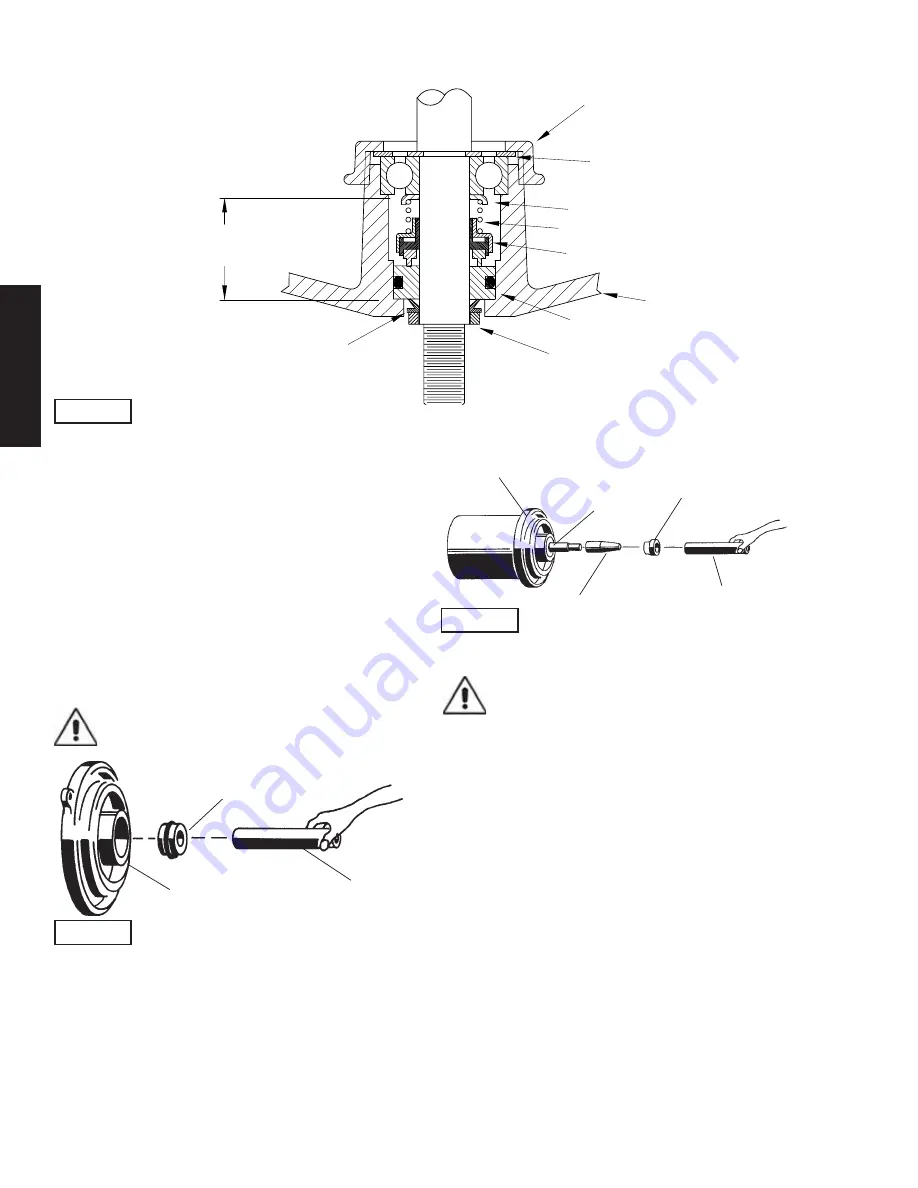

Seal -

Clean and oil seal cavity in lower end bell (10). Press

stationary member (1a) fi rmly into lower end bell (10), using a

seal pusher (see parts list - seal tool kit), nothing but the seal

pusher is to come in contact with seal face (see Figure 4).

Make sure the stationary member is in straight.

IMPORTANT ! - DO NOT hammer on the seal

pusher- it will damage the seal face.

Slide retaining ring (1d) over shaft and let rest on bearing

(21). Place spring (1c) over shaft and let rest on retaining ring

(1d). Lightly oil

(DO NOT use grease)

shaft, bullet and inner

surface of bellows on rotating member (1b), (see Figure 5),

with lapped surface of rotating member (1b) facing outward,

slide over bullet and onto shaft using seal pusher, making

sure spring (1c) is seated in retaining ring (1d) and spring (1c)

is lined up on rotating member (1b) and not cocked or resting

on bellows tail.

IMPORTANT ! - It is extremely important to keep

seal faces clean during assembly. Dirt particles

lodged between these faces will cause the seal to

leak.

Motor - Slide motor rotor with conduit bushing (16), washers

(25), (33) bearing (21) and seal parts (1b, c, d) into lower

end bell (10) until bearing (21) seats in lower end bell (10).

Center washers (25), (33) on bearing (21) and tighten conduit

bushing (16) on lower end bell (10).

Lower motor stator over rotor until seated in lower end bell

(10), while aligning holes for motor bolts. Insert motor bolts

and torque to 17 inch pounds. If pump is a single phase unit

place bracket (17) on one of the motor bolts. Insert capacitor

(18) in bracket (17), attach motor leads with fl ag terminals to

capacitor and place terminal boot (15) over terminals.

Set motor housing (11) next to motor (14) and lower end bell

(10) assembly. Make wire connections per paragraph F-3.3.

Set square ring (23) in groove on lower end bell (10) and

lower motor housing (11) down onto lower end bell (10) while

aligning holes. Place socket head cap screws (36) through

lower end bell (10) into motor housing (11) and torque to 60

inch pounds. Assemble impeller and volute per paragraph F-

2.2.

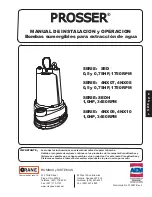

Stationary Member (1A)

Polished Face Out

Lower End Bell (10)

Seal Pusher

FIGURE 4

Rotating Member (1D)

Bullet

Motor

Seal Pusher

Stationary

FIGURE 3

SEAL ASSEMBLY (1)

RETAINING RING (1D)

LOWER END BELL (10)

SPRING (1C)

ROTATING MEMBER (1B)

STATIONARY (1A)

CONDUIT BUSHING (16)

WASHER (25) & (33)

SPACER (32) and

SHIMS (39) & (40)

EXCLUSION SEAL (31)

MOTOR END

(INBOARD END)

PUMP END

(OUTBOARD END)

FIGURE 5

E

N

G

L

I

S

H

Summary of Contents for PROSSER 4NX07 Series

Page 14: ...14 FIGURE 8 Series SED 4NX07 4NX08 E N G L I S H ...

Page 15: ...15 FIGURE 9 Series SEDH 4NX09 4NX10 E N G L I S H ...

Page 16: ...16 FIGURE 10 SEDH Series 4NX09 4NX10 SED Series 4NX07 4NX08 Series SED SEDH 4NX E N G L I S H ...

Page 35: ...15 SP E S P A Ñ O L FIGURA 8 Serie SED 4NX07 4NX08 ...

Page 36: ...16 SP E S P A Ñ O L FIGURA 9 Serie SEDH 4NX09 4NX10 ...

Page 42: ...E S P A Ñ O L ...