6

SECTION B: GENERAL INFORMATION

B-1) To the Purchaser:

Congratulations! You are the owner of one of the fi nest pumps

on the market today. CP&S pumps are products engineered

and manufactured of high quality components. Over one

hundred years of pump building experience along with a

continuing quality assurance program combine to produce a

pump which will stand up to the toughest applications. This

manual will provide helpful information concerning installation,

maintenance, and proper service guidelines.

B-2) Receiving:

Upon receiving the pump, it should be inspected for damage

or shortages. If damage has occurred, fi le a claim immediately

with the company that delivered the pump. If the manual

is removed from the packaging, do not lose or misplace.

B-3) Storage:

Short Term-

CP&S Pumps are manufactured for effi cient

performance following short inoperative periods in storage.

For best results, pumps can be retained in storage, as factory

assembled, in a dry atmosphere with constant temperatures

for up to six (6) months. Long Term- Any length of time

exceeding six (6) months, but not more than twenty-four (24)

months. The unit should be stored in a temperature controlled

area, a roofed over walled enclosure that provides protection

from the elements (rain, snow, wind-blown dust, etc.), and

whose temperature can be maintained b40 deg. F

and +120 deg. F. (4.4 - 49°C). Pump should be stored in its

original shipping container. On initial start up, rotate impeller

by hand to assure seal and impeller rotate freely. If it is

required that the pump be installed and tested before the long

term storage begins, such installation will be allowed provided:

1.) The pump is not installed under water for more than

one (1) month.

2.) Immediately upon satisfactory completion of the test,

the pump is removed, thoroughly dried, repacked in the

original shipping container, and placed in a temperature

controlled storage area.

B-4) Service Centers:

For the location of the nearest Prosser Service Center, check

your Prosser representative or Crane Pumps & Systems, Inc.

Service Department in Piqua, Ohio, telephone (937) 778-8947

or Crane Pumps & Systems Canada, in Brampton, Ontario,

(905) 457-6223.

SECTION C: INSTALLATION

C-1) Location:

Water feeding and discharging for construction and civil

works; Water supply and sewage works; Various kinds of

industrial facilities; Housing and building facilities.

The pump can be used at almost all places but avoid

continuous short-water operation at a sandy place, such may

accelerate wear of the pump. Install the pump at a position

where water can be collected most easily. When the pump is

installed on soft muddy or sandy ground, lay wooden board

or block under the body.

DO NOT allow pump to be buried

in mud or sand.

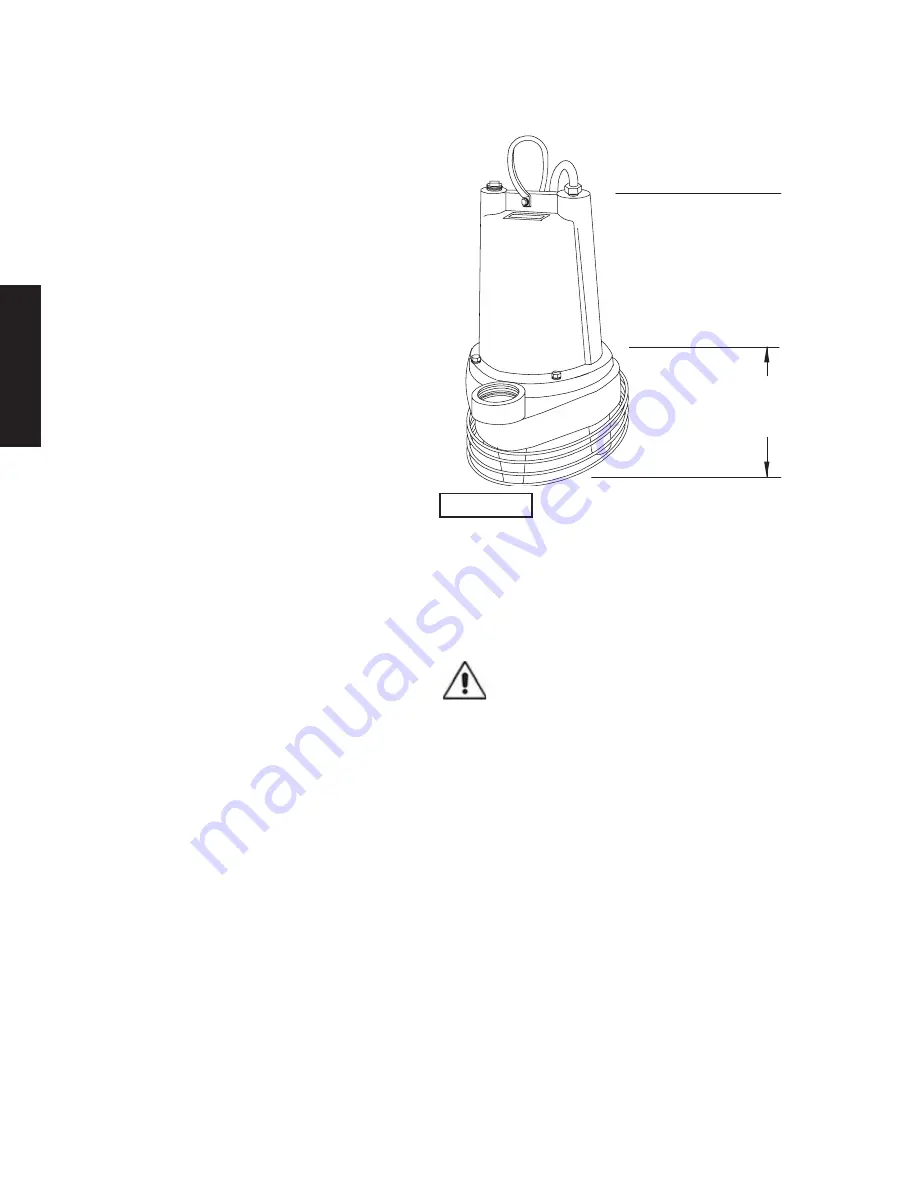

Submergence:

It is recommended that the pump be operated in the

submerged condition and the sump liquid level should never

be less than dimension “A” in Figure 1.

Before pumping fl uids other than water, consult the factory,

giving fl uid, fl uid temperature, specifi c gravity, viscosity,

capacity in USGPM and total head and/or pressure

requirements, including friction loss through discharge line,

fi ttings, valves, etc. Maximum fl uid temperature for sustained

operation is 104°F (40°C) at specifi c gravity 1.0.

IMPORTANT ! - Pump should have strainer

affi xed at all times. Inspect and clean the pump

strainer periodically for maximum effi ciency and

performance.

C-2) Discharge:

When any hose is used for connection, keep the hose as

straight as possible as excessively bent hose reduces water

quantity. Refrain from placing the discharge port (end of hose

or pipe) under water. Inverse fl ow may sometimes be resulted

due to siphon effect when the operation is stopped.

C-3) Electrical Connections:

C-3.1) Power Cord:

The cord assembly mounted to the pump must not be

modifi ed in any way except for shortening to a specifi c

application. Any splice between the pump and the control

panel must be made in accordance with the electric code

and all applicable state, province and local electric codes. It

is recommended that a junction box, be mounted outside the

sump or be of at least Nema 4 construction if located within

the wet well.

DO NOT USE THE POWER CORD TO LIFT

PUMP!

FIGURE 1

E

N

G

L

I

S

H

Recommended Submergence Level

Minimum Submergence Level

Bottom of Feet

A = 7.00

(178)

Summary of Contents for PROSSER 4NX07 Series

Page 14: ...14 FIGURE 8 Series SED 4NX07 4NX08 E N G L I S H ...

Page 15: ...15 FIGURE 9 Series SEDH 4NX09 4NX10 E N G L I S H ...

Page 16: ...16 FIGURE 10 SEDH Series 4NX09 4NX10 SED Series 4NX07 4NX08 Series SED SEDH 4NX E N G L I S H ...

Page 35: ...15 SP E S P A Ñ O L FIGURA 8 Serie SED 4NX07 4NX08 ...

Page 36: ...16 SP E S P A Ñ O L FIGURA 9 Serie SEDH 4NX09 4NX10 ...

Page 42: ...E S P A Ñ O L ...